Aluminum Die Casting Handles are used as drawer pulls, door handles, and basically anything that can be opened or closed that requires a handle to be used. Initially, homeowners think that the best aluminum handles or aluminum die casting hardware …

Continue reading

Category Archives: Aluminum Die Casting

Airplane Bracket Castings

Spotting Bracket Die Castings in several very different locations is interesting. While I was traveling in a Boeing 747-700 Airplane I discovered that the “Seat-Back Tray-Table” is held up using by two aluminum die casting parts as Bracket Castings. These bracket castings were attached to the seat back of the seat in front and to a plastic tray table. These aluminum bracket die castings are painted white to match their surroundings. These aluminum brackets are strong enough to hold a laptop or a plate of food or even the hands of someone working a puzzle or a book. These brackets are strong because they are designed using geometry that gives the bracket casting strength with corner radii and ribs and gussets.

Aluminum Die Casting Airplane Parts are very common. Most airplanes are made from aluminum as the metal of choice. Aluminum die castings are lightweight and strong.

Bracket Castings on Boeing 747-700 Airplane

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Aluminum Heat Sink Diecastings

Manufacturers are specifying the die casting process to make heatsinks in aluminum. What are Aluminum Heat Sinks? The material, aluminum, has great thermal conductivity.

Aluminum Die Casting Heat Sinks

Aluminum is a strong and durable material, which is why this is an ideal metal to use in heat sinks. This metal is found in the earth and is extracted from ore. Some say that it is more valuable than gold even though it is very abundant since this metal can be used in a variety of ways due to its unique characteristics of being strong, durable yet light in weight. It is used as a part of many appliances people commonly use as well as electronics. Aluminum Heat Sinks are just one of the products made with this metal.

Video of the die casting metal flow into a die casting mold to produce an Aluminum Heat Sinks.

Aluminum Heat sinks have one purpose, and that is to take away the heat from more sensitive parts in the appliance or electronic product it is in. Since electricity produces heat, it can damage the product. By placing a Die Casting Aluminum Heat Sink, the heat is diverted from the wires, boards and other more important parts of the product so that it can continue to function. Since aluminum is a very durable material, it is ideal for this job.

Now, Aluminum Heat sinks are made by using the die casting process, a process which involves melting the aluminum first. The liquid metal will then be injected into molds, these molds will give the metal its new shape. Once the molds are cooled, it can now be opened and that’s it, a new heatsink has been finished. Since heat sinks are used by a lot of manufacturers, they are needed in large quantities. Die casting is the best way to provide large numbers of Aluminum Heat Sinks since it is a fast, cheap and reliable method.

Permalink: https://www.kineticdiecasting.com/kdc/aluminum-heat-sink-diecastings/

Kinetic Die Casting manufactures custom metal parts to their customer. If you would like more information about Kinetic Die Casting, please visit our website:Kinetic Die Casting Company

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Recycling Aluminum Die Castings

Die casting Parts are completely recyclable. Die Casting Parts have a Planet-Saving Value. These days, many manufacturers are turning to aluminum.

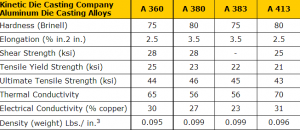

aluminum die casting alloys

Aluminum is a better material to provide their businesses with excellent products that can boost sales. Die casting aluminum is more than just an aluminum production means; it is considered both as an art and a craft.

Unlike plastic, aluminum alloys are completely recyclable. Aluminum is strong and does not deteriorate over time.

Permalink: https://www.kineticdiecasting.com/kdc/recycling-aluminum-die-castings/

The aluminum die casting alloys used in the aluminum die casting process offer designers that are concerned with post-consumer recyclable a highly favorable material option by way of the die cast parts’ reuse feature. Die cast aluminum parts these days, as well as the entire die casting process itself, give product engineers the chance to create and develop aluminum designs that can save the environment. Thus, components in the die casting process are now made to maintain their integrity and quality through disassembly and the consequent tasks of repair, manufacturing, and reassembly – major options that were not available or possible in past years.

What does all this mean? It means that once the lives of die casting aluminum parts end, they are armed with the potential to return to usefulness by becoming part of some other industrial application, and an Kinetic Die Casting Company an aluminum die casting company can indeed help save the planet.

Kinetic Die Casting manufactures products like aluminum hardware, and aluminum boxes. If you would like more information on Kinetic Die Casting, please visit our website:Kinetic Die Casting Company

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Aluminum Box Enclosure Uses

Die Casting Aluminum Boxes are used in many ways. How are Die Casting Aluminum Box Enclosures used? These boxes are used for retail product packaging because they can easily get grounded since aluminum can conduct electricity. These are also used as enclosures for parts which should be protected from sudden impact, dust, or moisture. These boxes are also used as a means of blocking away radio waves and frequency which may affect the capacities of the electronic components. It offers protection to the electronic components by providing RF or EMI shielding.

Aside from these uses, a die casting aluminum box enclosure is also utilized as a “grounding plane” or as a common electrical circuit for the electrical machinery inside the box. Die casting aluminum boxes can also be used as storing equipment since they are durable enough to contain materials when one is out on a road trip. These boxes can be manufactured huge so these can be used at the back of pick up trucks. But they can also be crafted in a small size so they can be used in the home as storage for magazine and comic book collections. These can also be used as mailboxes which can survive the harsh weather for a couple of years. Die casting aluminum boxes are also used as large transportation enclosures for both equipment and animals.

Permalink: https://www.kineticdiecasting.com/kdc/aluminum-box-enclosure-uses/ ?

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Aluminum Bracket Diecastings

Brackets are used for mounting electronic devices. Electronic devices are usually fragile and need a single fall before being permanently damaged like aluminum guitar amplifiers. Another problem is that many of these items are usually mounted onto walls to save space and to increase their output. A good method to solve this problem is by simply putting these items on top of other surfaces. However, this reduces the quality of their output. The best solution is to purchase aluminum brackets to safely secure the electronic items on the wall.

Aluminum brackets are L-shaped pieces of metal that are used in pairs to make a surface for mounting electronics. These are oftentimes used in mounting speakers and other sound related electronics. The more recent application for this item is the mounting of computer monitors and flat screen televisions onto the wall. The variety of brackets that are used for this purpose have a swivel feature which allows the user to adjust the screen.

When purchasing aluminum brackets, it is important to first determine the product on which the bracket would be used on. This would dictate the type of bracket that could be used, the weight carrying capacity of the bracket, and the features that could be present in the bracket. Although this may seem as a hindrance for most people, it actually is not. Brackets are usually labelled with the products that they are compatible with so that customers do not have to bring their electronic items along with them. Also, brackets may come with the package of the electronic item being purchased making it redundant to purchase brackets in the first place.

This is the blog on the Kinetic Die Casting Company web site. We are an American Die Casting Company. Look at this website page for more details: www.kineticdiecasting.com/american_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html