Contacting Kinetic Die Casting Company. Recently, we have had a few miscommunications with our company. We received a purchase order (PO) three months late because our customer sent the PO to an old contact email address. The following is the …

Continue reading

Category Archives: Aluminum Die Casting

The Aluminum Lighting Parts vs. Steel

The Aluminum Lighting Parts vs. Steel. Aluminum and steel are metals that have been the best choices for lighting parts. They’re both durable and readily available in the market. However, in this article, you will find out why choosing aluminum is better.

The Aluminum Lighting Parts vs. Steel. Aluminum and steel are metals that have been the best choices for lighting parts. They’re both durable and readily available in the market. However, in this article, you will find out why choosing aluminum is better.

First of all, it is easier to modify an aluminum product than a steel product. A set of simple tools is enough to cut, sharpen and weld aluminum. Changing a lighting part made of aluminum would take less time and effort than having a lighting part made of steel, which is harder to alter.

Furthermore, Lighting parts made of steel are also considerably heavier than the ones made of aluminum die casting, adding more weight to the car. This may sound like a good thing, but an extra weight will make steering a bit difficult.

Also, broken aluminum lighting parts can be sold at a higher price than the ones made from steel.

An aluminum lighting part needs not to be painted unlike a steel one to prevent it from rusting. It will also not require a re-painting job once the paint smudges off. This will help you cut back on expenses.

The advantages of aluminum lighting parts over steel listed in this article should help one in deciding what to buy and what not to buy.

Light Fixture Die Casting Parts

Kinetic Die Casting Company makes aluminum die castings as Lighting Fixture Die Castings. We make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

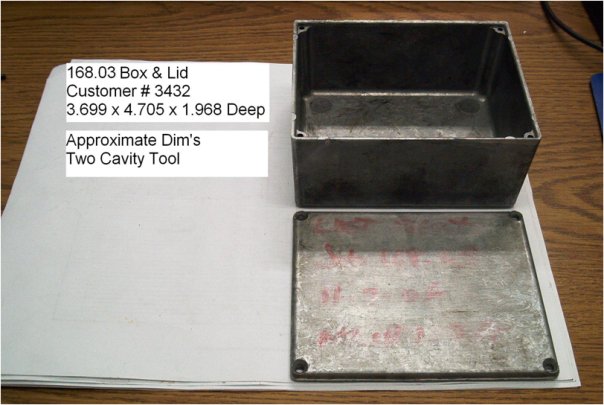

Die Casting Aluminum Boxes made by Kinetic Die Casting Company

Die Casting Aluminum Boxes made by Kinetic Die Casting Company. If you are looking for boxes which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 15 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Boxes made by Kinetic Die Casting Company. If you are looking for boxes which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 15 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum boxes through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a die cast or steel die cast mold. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the boxes are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Artmold Die Casting Company Closure

ArtMold Die Casting Company

11872 Sheldon Street,

Sun Valley, California 91352

Phone: 818-767-6464

ArtMold Die Casting Company is closing. Artmold was located at 11872 Sheldon Street, Sun Valley, CA 91352 Ph: 818.767.6464.

Artmold Die Casting Company Closure

I received a phone call on 15 June, 2016 from Leo one of the ArtMold owners that they are closing down their die casting production and die casting operations. Artmold was just a few miles away from us here at Kinetic Die Casting Company in North Hollywood.

If you are a die casting customer to Art Mold Diecasting, call Kinetic Die Casting Company at 818-982-9200 to arrange to pick up your die casting tooling and make your die casting parts.

Kinetic Die Casting Company (http://www.kineticdiecasting.com)

6918 Beck Avenue, North Hollywood, CA 91605

Phone: 818-982-9200

Read more about the Kinetic Die Casting History here: http://www.kineticdiecasting.com/history.html

Methods for Making Aluminum Hardware

Methods for Making Aluminum Hardware. Hardware brackets are produced and used in many industries today, which is why it is a very important component that should be made and processed properly and correctly. Aluminum brackets are made as parts for lighting fixtures, automobiles, and even in construction because its main purpose is to keep all the parts stable, steady, and as much as possible, long lasting. Before, manufacturers would use steel to make these hardware brackets and would have to weld the pieces together. But these welded pieces become weak overtime, which makes it expensive, time-consuming, and you’d have to exert a lot of effort just to maintain it.

Therefore, this is why many manufacturers now see the advantages they get when they use aluminum die castings to make their hardware brackets. Die casting involves a process of forcing molten metal under high pressure to be able to produce complex yet more tolerable molds to create parts and housings for different things such as military weapons and die casting lighting fixtures. When making hardware brackets, manufacturers would create them using the process of aluminum die casting, afterwards shaping it easily into parts that they know would make it sturdier, more long-lasting, and of course cost-efficient as compared to steel.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Chassis Castings Over Steel Advantages

Aluminum Chassis Castings Over Steel Advantages. High pressure die casting is the process used to make aluminum die cast parts and chassis castings. This process is now becoming more and more popular in several major manufacturing industries because of its many advantages.

Furthermore, Aluminum is a great metal to work with. Unlike other metals, it has plenty of strengths. The metal can be found almost everywhere in the planet. Supply will not run out, so it is easy to acquire and not heavy on your pockets.

Advantages of aluminum chassis castings over steel include:

- Aluminum can be stronger than steel

- three times greater axial load strength

- Faster production rate. In fact, production quantities can be done within a few days instead of several weeks!

- Fewer failures and returns to the OEM

- Weight is lighter by two and a half times for lesser shipping costs

- Less finishing costs

- Raw parts manufacturing costs are much less

- Better looking parts

Also, you can produce aluminum die casts according to your preference and specifications, such as the trim, clean, machine, inspect, powder coat and the package of your aluminum cast parts.

The use of aluminum castings over still helps you reduce weight, boost strength, and save you more money.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com