The advantages of Aluminum Audio Speaker Parts over plastic. If you are to match aluminum audio speaker parts against plastic audio speaker parts, which do you think is better? First of all, the first thing that you will notice with …

Continue reading

Category Archives: Blogger

Plastic Parts For Military

There many advantages of aluminum military parts over plastic parts. Being in the military force is a life-threatening job. Together with this risk is the honor of saving one’s territory, which is one of the reasons why a number of men choose this as their career path. However, their success does not depend on their skills alone. The equipment to be used should also be considered. Look at these Night Vision Goggles made by Kinetic Die Casting Company. We made over 200,000 sets of these aluminum military parts for our customer.

To help the military in fulfilling their goal, they should know the advantages of aluminum military parts over plastic military parts. Why? Plastic military parts may be cheaper, but it cannot match the advantages given by aluminum military parts. Aluminum military parts can withstand prolong stocking periods. When not in battle, the equipment tend to be stored in the barracks. Unfortunately, some of these fade quickly in terms of quality and usability. It is because some parts are made of a special plastic which is not capable of keeping its condition over time. Aluminum does this, even if exposed to strong chemicals. Moreover, plastic parts are highly vulnerable to damage due to strong impacts. For instance, a rifle had to be dropped. The damage it can give to an aluminum part would not be that severe, but it would be very different for a plastic military part.

These are only a few of the many advantages of aluminum die casting military parts over the plastic parts.

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

What Are Die Casting Parts?

Die Casting Aluminum Heat Sinks

Aluminum Boxes Diecastings

Aluminum Parts or Plastic Parts

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Closed Independence Day 2019

Happy 4th of July. Independence Day celebrates the signing of our Declaration of Independence on July 4, 1776. The Continental Congress declared that the thirteen American colonies regarded themselves as a new nation, the United States of America, and were no longer part of the British Empire. The Congress actually voted to declare independence two days earlier, on July 2.

Independence Day is commonly associated with fireworks, parades, barbecues, carnivals, fairs, picnics, concerts, baseball games, family reunions, and political speeches and ceremonies, in addition to various other public and private events celebrating the history, government, and traditions of the United States. Independence Day is the National Day of the United States.

Happy 4th of July from Kinetic Die Casting Company.

God Bless America

We are closed Thursday, July 4th 2019 in celebration of our nations independence. We will also be closed on Friday. We will be returning Monday our regular hours. God Bless America. We hope that your first half of the year was prosperous and also hope that you year continues to be prosperous.

Permalink: https://www.kineticdiecasting.com/kdc/closed-independence-day-2019/

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

818-982-9200

sales@kineticdc.com

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Lighting Part Die Castings 2019

Kinetic Die Cassting Company makes Aluminum Lighting Fixture Parts. Aluminum die casting is a lightweight, non-toxic, and non-magnetic metal. It is also resistant to corrosion and can be easily molded and formed into many different shapes. Additionally, there is plenty of aluminum to be had so issues regarding the availability of the metal are nil. Because of these properties, aluminum is one of the most ideal metals for the production of various goods, such as lighting fixtures.

Die casting aluminum lighting fixture parts can be found in various medical lighting products as well as in medical offices where there are hanging light fixtures made from aluminum. Other examples of aluminum lighting fixture parts are endcaps on light fixtures and housings for various kinds of light fixtures, such as parking garage lighting, street traffic lights, walk lights, and high temperature lights. Aluminum lighting fixture parts also come in the form of decorative lighting poles manufactured from rustproof aluminum that is given extra protection against rusting by a powder coat finish. Additionally, aluminum is utilized for light fixtures themselves, such as bullet light fixtures, wall sconce fixtures, and outdoor coach lights. Even though aluminum is lightweight, the metal is highly resilient against extreme weather conditions and seasonal changes. Additionally, the production of aluminum lighting fixture parts is generally cost-effective as aluminum is quite inexpensive.

“The Parts We Make Today, We Ship Today”

What is Die Casting?

Costs Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Parts

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Permalink: https://www.kineticdiecasting.com/kdc/lighting-part-die-castings-2019/

Summer Solstice 2019

June 21 is the first day of summer and is called the Summer Solstice. This is the longest day of the year, we get the most daylight on this day than any other day of the calendar year. The Sun reaches its most northern point in the sky at local noon. After today, the days start getting shorter. The word solstice is from the Latin solstitium, from sol (sun) and stitium (to stop), reflecting the fact that the Sun appears to stop at this time (and again at the winter solstice).

Permalink: https://www.kineticdiecasting.com/kdc/summer-solstice-2019/

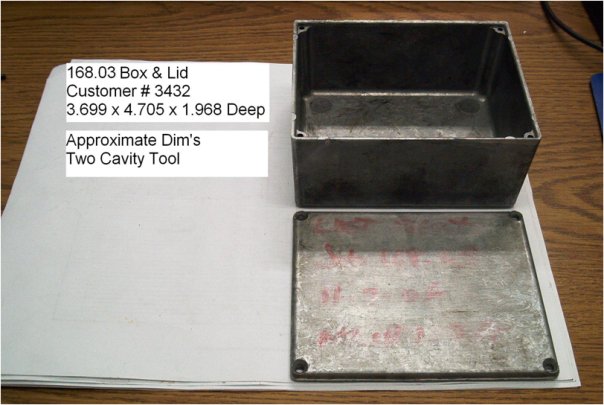

Diecast Enclosures 2019

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum enclosures through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a steel die casting mold tool. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the enclosures are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Enclosures. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting parts every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com