How Are Aluminum Automobile Parts Made? Cars needed to be in top quality since they are frequently used by people. To do this, every part that is included in the vehicle should also be of good condition. How do vehicle-producing …

Continue reading

Category Archives: Blogger

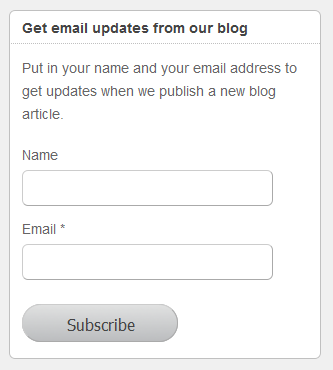

Kineticdc Newsletter Signup

Kinetic Die Casting sends out a Company Email Newsletter from our die casting company blog

to our customers, friends, and other subscribers. This is a “Subscription Only Newsletter“.

How do I sign up for this newsletter?

The newsletter is a “opt-in Newsletter”. Go to our die casting blog (www.kineticdiecasting.com/kdc/) and look to the right sidebar for the sign up link.

A confirmation email will be sent to your email address. Confirm by clicking the link sent to your email address.

Our Newsletter has various topics, such as:

- Save money with die castings

- Educational Topics (Money saving ideas)

- Customer Success Stories / Customer tips

- Kinetic Die Casting Company Updates and Discounts

Sign up to our email newsletter using the link on our blog. You will be able to safely unsubscribe anytime by sending an email to sales@kineticdc.com.

Your email address will never be shared or sold

(See Privacy Statement).

This email newsletter will give us a chance to send you information that is helpful to you and your company. Some of the tips will save your company money by informing you of ways to take advantage of the benefits of die castings.

Happy Thanksgiving from Kineticdc 2016

Kinetic Die Casting Company wishes all our friends and customers a Happy Thanksgiving in 2016. We are taking a long lunch today A company. Please call again after 1:00 PM if we do not answer. We will be closed November 24th and 25th, 2016 to be with or families in observance of Thanksgiving. Please enjoy the time with your family during the start of the holiday season.

Enjoy Your Thanksgiving Dinner

Kinetic Die Casting Company – E-mail sales@kineticdc.com

818-982-9200 – 800-524-8083 – Toll Free – 818-982-0877 Fax

6918 Beck Avenue North Hollywood, California USA 91605

Permalink: https://www.kineticdiecasting.com/kdc/happy-thanksgiving-from-kineticdc-2016

Kinetic Die Casting Company makes aluminum parts and zinc parts, on time, for most manufacturing industries.

The parts we make today, we ship today.

Thanksgiving Lunch on November 23

Kinetic Die Casting Company will be closed for a long lunch on November 23 in celebration of Thanksgiving in 2016. If you call and get no answer, please call again after 1:00 PM. We will be closed November 24th and 25th, 2016 to be with or families in observance of the Thanksgiving holiday.

Permalink: https://www.kineticdiecasting.com/kdc/thanksgiving-lunch-on-november-23/

Kinetic Die Casting Company

6918 Beck Avenue North Hollywood, California, 91605, USA

800-524-8083 or 818-982-9200 or fax 818-982-0877

Use this e-mail link to send attachments: sales@kineticdc.com.

Chocolate Fountain Parts

Kinetic Die Casting Company makes an aluminum die casting part as a heater plate for a chocolate fountain. The heater plate transfers the heat from a heating element to a stainless steel bowl to melt chocolate. Aluminum die casting parts are used because aluminum has excellent properties for transferring heat and dissipating heat. Die castings are inexpensive compared to other aluminum part manufacturing processes.

A chocolate fountain is a device for serving chocolate fondue. Typical examples resemble a stepped cone, standing 2-4 feet tall with a crown at the top and stacked tiers over a basin at the bottom. The basin is heated to keep the chocolate in a liquid state so it can be pulled into a center cylinder then vertically transported to the top of the fountain by a corkscrew auger. From there it flows over the tiers creating a chocolate “waterfall” in which food items like strawberries or marshmallows can be dipped.

Permalink: https://www.kineticdiecasting.com/kdc/chocolate-fountain-parts/

Contact Kinetic Die Casting Company sales@kineticdc.com if you have an unusual aluminum part to die cast.

Click here for other ==> Photos of Die Casting Parts

Newsletter Signup –

1. Put your Name as you want to see it in the newsletter in the top location.

2. Put your valid Email * address in the bottom area.

3. Click the Subscribe button.

A confirmation email will be sent to your email address. Confirm by clicking the link sent to your email address.

EXPORTECH™ LOS ANGELES 2016

EXPORTECH™ LOS ANGELES for Aerospace & Defense Manufacturers.

The only national program that helps individual companies develop an export plan. Helping manufacturers achieve their export objectives and increase sales in global markets

Session 1: November 17, 2016 – Export Strategy & Best Practices – Exploring Strategic Options

Session 2: December 15, 2016 – Mechanics of Exporting – Removing Knowledge Gaps – Overcoming Obstacles

Session 3: January 26, 2017 – Export Growth Plan Presentations – Obtaining Expert Feedback – Individual Coaching – Plan Implementation and Go-to-Market

All sessions start at 7:30 a.m. and conclude at 5:00 p.m.

Continental breakfast: 7:30 – 8:00 a.m.

All sessions will be held at:

The Entrepreneur Center

13420 Van Nuys Blvd.

Pacoima, CA 91331

To register or for any questions please call Elizabeth Glynn at 310-984-0728 or eglynn@cmtc.com For additional information on exporting visit: www.cmtc.com/exporting

Department of Defense, Office of Economic Assistance is funding the majority of the program $5,000 value per company Your cost: ONLY $500 per company for all three sessions

NOTE: Must have been impacted by defense budget reductions. Check with CMTC for details.

Permalink: https://www.kineticdiecasting.com/kdc/exportech-los-angeles-2016/