2017 Purchase Order Terms. Thank you for trusting Kinetic Die Casting Company with your die casting production parts and die casting tooling needs. These terms and conditions are the same we have used since our founding in 1994. Please take …

Continue reading

Category Archives: Die Casting Parts

500 Shots Daily

Kinetic Die Casting Company uses a process of making 500 to 1000 aluminum die casting parts every day. Last week, in my multiple cavity die casting tool article, I briefly described the die casting shot cycle as: Die Open, Spray, Die Close, Inject Metal, Open Die, Eject Part and Repeat. This takes about one minute each shot cycle.

- Here are the details of each Step of the die casting production cycle:

- Die Open – The hydraulic system opens the die casting machine platens. The die casting mold is attached to the die platens, opening the die wide so the two halves can be accessed.

- Spray – Molten metal will stick to the steel die if a release agent is not used to coat the tool. The cavities, the slides, the core pins and ejector pins are sprayed also to cool them down.

- Die Close – When the die has been sprayed the machine is closed with hydraulic pressure so the two die halves are closed and sealed together. Sometimes, high pressure nitrogen gas is used to speed the die closing.

- Inject Metal – The metal is poured into the shot sleeve and a piston drives the molten metal into the mold. Hydraulic pressure is used to push the metal into the mold. Higher pressures are applied to push out gasses that cause porosity. High Pressure Nitrogen Gas is used to accelerate the piston faster and to add more pressure to squeeze out gasses.

- Open Die – The die casting machine opens the platens

- Eject Part – The Die casting machines moves a movable platen to push against the ejector plate. The ejector plate pushes the ejector pins. The ejector pins push the part out of the cavity

- – Repeat

In a nutshell, This is the die casting shot cycle. Each shot cycle takes about a minute to complete. We make 500 parts a day with a single cavity die.

Permalink: https://www.kineticdiecasting.com/kdc/500-shots-daily/

“The Parts We Make Today, We Ship Today”

What Are Die Casting Parts?

Die Casting Aluminum Heat Sinks

Aluminum Boxes Die Castings

Aluminum Parts or Plastic Parts

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

July 2019 Kinetic Die Casting Jobs

We prefer that people who live nearby our company to work for our company. We prefer that local applicants apply for open positions.

If you live far away from our company, we prefer that you relocate where you live to live near your job. We will not offer a job to someone who lives, in our opinion, too far from our company in travel time or distance. If you live in another state or if you live in a foreign country, we will not offer a job position unless there is a very good reason for us to consider your employment.

How to get the Kinetic Die Casting Company job:

- Click on the Online Job Application Button to complete our employment application online for position at Kinetic Die Casting Company.

- Send completed Job Application, Resume and Salary Desired

to Kinetic Die Casting Company for a Die Casting Job Interview.

Send:

Completed Job Application, Full Work Resume and Salary Expected

Mail to:

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood Ca. 91605

Attention: Human Resources

OR

* Fax: 818-982-0877 or

* Email: sales@kineticdc.com

==> 818-982-9200 < ==

Call to set up a job interview.

Permalink: https://www.kineticdiecasting.com/kdc/july-2019-kinetic-die-casting-jobs/

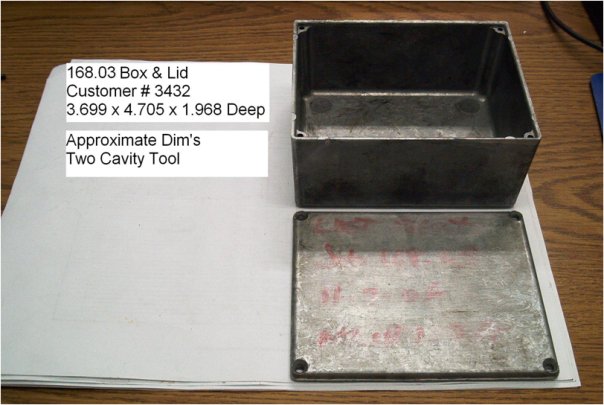

Diecast Enclosures 2019

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum enclosures through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a steel die casting mold tool. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the enclosures are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Enclosures. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting parts every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aerospace Diecastings

Kinetic Die Casting Company makes several types of Die Casting Aerospace Parts. These aerospace die casting parts are used for many types of purposes. Some of these parts are used on many types of aircraft, such as: airplanes, jet planes or helicopters.

Aircraft manufacturers typically specify aluminum die casting to make the aerospace parts because aluminum is lightweight and inexpensive as well as very strong.

- Lightweight – Aluminum weighs only .098 pounds each cubic inch of material as compared to zinc which weighs about 2.44 pounds each cubic Inch.

- Inexpensive – Aluminum is the third most common element on earth, so it is more available than other materials. Aluminum is used in over 80% of all die castings produced in the world.

- Strong – Aluminum parts can be geometrically designed to be stronger than steel. Look up “aluminum is stronger than steel” on Google to see the results.

These aerospace parts range from: airplane engine piston heads, airplane distributor cap housings, fuel system parts, detention ring parts, cargo loading housings, lighting fixture parts, electronic enclosures, electronic housings, motor housings and various other aluminum die casting parts.

The companies that trust us to purchase their die casting parts from Kinetic Die Casting Company are many.

- Here are a few of the aircraft and aerospace companies that we can name:

- Robinson Helicopter

- Ancra International

- Whittaker Controls

- AAR Cargo Systems

- Boeing Aerospace

- Barry Controls

- Meggitt Aerospace

- Parker Hannifin Aerospace Corporation (Parker FSD)

- Circle Seal Aerospace

- Kelly Aerospace

- Curtiss Wright

- Honeywell

- United Technologies Aerospace

Low Quantities.

Many of these companies order lower quantities. One of the companies listed here will order less than 50 parts at a time. Many of these companies order 250 parts or less. Kinetic Die casting will accept any purchase order quantity.

Permalink: https://www.kineticdiecasting.com/kdc/aerospace-diecastings/

Contact Kinetic Die Casting Company when you need any of the following: Low Quantities, Great Quality, Fast Delivery.

“The Parts We Make Today, We Ship Today”

Aluminum Heat Sinks

Die Casting Car Parts

Aluminum Hardware Brackets

Aerospace Die Casting Parts

Military Die Casting Parts

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Process

Kinetic Die Casting Company uses the die casting process to make aluminum die castings and zinc die casting parts. The die casting process, simplified, is described as follows:

- Our customer provides us tooling (https://www.kineticdiecasting.com/tooling.html), a die, a mold or inserts that we use to make their parts. We can also produce the tooling for our customers.

- We put together the tooling and mount the tooling in our die casting machine. This takes a few hours.

- We fill a furnace with the proper die casting alloy metal (https://www.kineticdiecasting.com/Alloy_Data.pdf) to make the parts for our customer. The metal takes 4 hours to melt to the casting temperature.

- While the furnace is heating up we heat up the tooling to make the castings.

- When the tooling is hot and the furnace has melted the aluminum, we begin the die casting process.

- We spray the tooling with a release agent so the parts do not stick in the tooling.

- We close the tooling inside our die casting machine.

- The metal is ladled into a shot sleeve, a piston drives the metal into the tooling using great force.

- Our die casting machine opens, the ejector pins push the part out of the tooling

- We begin the process again by spraying the tooling.

- We repeat this process 200 times to 500 times in a 10 hour shift.

- When completed making raw castings, we trim the excess material called “flash”. We use a trim die in a trim press or we sand parts with a belt sander and file them by hand. Sometimes this takes longer than the casting process.

- At this point, some parts are put in boxes and shipped the same day. Other parts are machined. Some parts get painted or chemical coated. All parts are inspected prior to shipping to our customers.

This is a very simplified description of the die casting manufacturing process.

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

What is Die Casting

Die Casting Part Pictures

Quote Die Casting Part Prices

Diecast Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Permalink: https://www.kineticdiecasting.com/kdc/die-casting-process/