I received a phone call in recent weeks from our national organization, North American Die Casters Association of die casting companies (NADCA) about Arrow Diecasters. Somehow, NADCA did not know that Arrow Die Casting Company was closed. Arrow closed a …

Continue reading

Category Archives: Die Casting Parts

Aluminum Parts and the Tooling

Aluminum Parts and the Tooling. Aluminum die casting need a lot of tools and parts to make the perfect dies. The process has been well known to provide an easy method for many constructors to create the most ideal components to different automobiles and the likes. Aluminum parts types are not that easy to characterize especially for a person who is quite new in the die casting process. Since the system also involves a series of molten metals from copper, lead and zinc, a lot of aluminum part types are needed to come up with the best die that possesses the exact instructions by the client. Cold chambered and hot chambered are just two of the aluminum parts types specifically used for the actual machine in die casting.

Aluminum Parts and the Tooling. Aluminum die casting need a lot of tools and parts to make the perfect dies. The process has been well known to provide an easy method for many constructors to create the most ideal components to different automobiles and the likes. Aluminum parts types are not that easy to characterize especially for a person who is quite new in the die casting process. Since the system also involves a series of molten metals from copper, lead and zinc, a lot of aluminum part types are needed to come up with the best die that possesses the exact instructions by the client. Cold chambered and hot chambered are just two of the aluminum parts types specifically used for the actual machine in die casting.

Die casters choose to apply all aluminum part types while die casting. This makes the process more experimental, and can sometimes produce the best outputs at the end of the sessions. However, there is a startling difference between a cold chambered die casting machine from a hot chambered one. For instance, a die caster cannot simply use hot chambered types when dealing with aluminum material. This type of material is more compatible to a die casting machine that is cold chambered. Molds for aluminum die casting may also have parts that do not need cavities. This type of mold greatly differs in price compared to those with cavities.

Furthermore, a lot of the parts sold for aluminum die casting often come with substantial product descriptions to let you determine which of the aluminum part types you are about to purchase like Aluminum Handle Hardware and Aluminum Bracket Hardware.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Different Types of Aluminum Castings

Different Types of Aluminum Castings. Aluminum die castings are used to by a lot of metalworking companies to form the perfect aluminum material, without having to spend a lot of money and wasting a lot of time. Due to the versatility of these processes, a lot of companies have turned to this unique way in forming one of the most dependable alloys that is used for several components in the same industry. There are a lot of items that were produced out of aluminum castings from the Washington Monument’s cap to the ancient tea kettles used by people who lived hundreds and hundreds of years ago. Although there have been a lot of improvements in the process of aluminum castings, most of the companies still resort to the traditional means of using molten metal to form some of the most intricate dies in history.

Different Types of Aluminum Castings. Aluminum die castings are used to by a lot of metalworking companies to form the perfect aluminum material, without having to spend a lot of money and wasting a lot of time. Due to the versatility of these processes, a lot of companies have turned to this unique way in forming one of the most dependable alloys that is used for several components in the same industry. There are a lot of items that were produced out of aluminum castings from the Washington Monument’s cap to the ancient tea kettles used by people who lived hundreds and hundreds of years ago. Although there have been a lot of improvements in the process of aluminum castings, most of the companies still resort to the traditional means of using molten metal to form some of the most intricate dies in history.

Furthermore, Aluminum castings can come in three diverse methods. Out of the three (permanent mold casting, sand casting and die casting), die casting is considered as the most popular among all companies in the metalworking industry. Although sand casting is known to be more versatile due to its delicate patterns, die castings prove to produce the most durable components used by a lot of automobile franchises and even the smallest of modern electronic gadgets. Other would say, however, that permanent mold castings also produce durable materials, but may need more expensive equipments and methodologies compared to the two other methods. Although these three processes may have a lot of differences, it can be agreed that aluminum die castings are highly effective in whichever method they are performed under.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

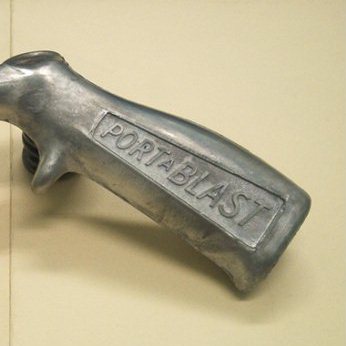

Aluminum Hardware Handles-Die Casted

Die Casted Aluminum Hardware Handles. Hardware handles are made specifically to open doors among other things. This means that these handles are designed to be pushed, pulled and bluntly, take a lot of punishment throughout their existence. Because of that, hardware handles need to be very strong and very durable so that it can last a long time. With that in mind, what better way to make these handles than with aluminum? Aluminum Hardware Handles are essentially stronger and much more durable than any other handle of different material including steel. At the same time, Aluminum Hardware Handles are very light, and of course, cheap.

Die Casted Aluminum Hardware Handles. Hardware handles are made specifically to open doors among other things. This means that these handles are designed to be pushed, pulled and bluntly, take a lot of punishment throughout their existence. Because of that, hardware handles need to be very strong and very durable so that it can last a long time. With that in mind, what better way to make these handles than with aluminum? Aluminum Hardware Handles are essentially stronger and much more durable than any other handle of different material including steel. At the same time, Aluminum Hardware Handles are very light, and of course, cheap.

Furthermore, Aluminum can be mined in the earth and are extracted from ore. Even if people consider this to be a very valuable material because of its unique characteristics, it is cheap because it can be found in abundance. In molding this material into the proper shape, the best method is die casting.

Also, Die casting is the process of turning metal into a finished product. Aluminum is commonly used in this process but zinc and copper can also be used. The first step is to turn the metal alloy into liquid by heating it. When the metal is already liquefied, it will be injected to molds that will shape the metal into Aluminum Hardware Handles.

Die Casting Aluminum Hardware Handles would result in consistent products with high quality. At the same time, it is a fast and efficient process in producing aluminum based parts. When it comes right down to it, companies and manufacturers truly benefits with die casting.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Monday Feb 22 We Deliver Almond Roca for Aerospace Die Castings

Did you know that Kinetic Die Casting Company makes Aerospace Die Casting Parts? We do. On Monday February 22, we will deliver Almond Roca to the buyer who purchased Aerospace Die Casting parts from our company.

We offered to give Homemade Almond Roca for any new purchase order placed in February 2016. Today, Monday February 22nd, we will be delivering Almond Roca to an Aerospace manufacturing company for placing a purchase order for 15,000 aluminum die casting parts as spacers. Thank you for the business.

Here is a list of a few of our Die Casting Aerospace Parts customers:

https://www.kineticdiecasting.com/kdc/die-casting-aerospace-parts/

Presidents’ Day 2016 and Almond Roca

Presidents’ Day 2016 – The third Monday in February is Presidents’ Day. Washington’s Birthday was a United States federal holiday.

This holiday, celebrated on the third Monday of February in honor of George Washington, our first President of the United States. Now, this day is known as Presidents Day, and is often an occasion to remember all the U.S. presidents, not just George Washington’s actual birthday, February 22 or Abraham Lincoln, whose birthday is February 12th. The term “Presidents’ Day” used to change the holiday into a day honoring multiple American presidents.

Recently, the February holiday is a day in which many retail stores, especially furniture stores and car dealerships, hold discount sales. Until the late 1980s, banks and corporate businesses closed on this day, similar to present corporate and bank practices on Memorial Day or Christmas Day. With the late 1980s advertising push to rename the holiday, more retail businesses are staying open during the holiday each year, and, as on Martin Luther King Jr. Day, Veterans Day and Columbus Day. Many colleges and universities hold regular classes and operations on Presidents’ Day. Most U.S. Postal Service delivery services offer regular service on the day.

Happy Presidents’ Day – Kinetic Die Casting Company will be open on this day for regular hours to serve our customers. We are currently shipping our new production part purchase orders in 4 weeks. We are thankful to our customers for their production parts they purchase from us.

Kinetic Die Casting Company

6918 Beck Avenue, North Hollywood, CA 91605

Email: sales@kineticdc.com – Telephone: 1-818-982-9200

To get die casting part prices:

http://www.kineticdiecasting.com/replyform.html

Homemade Almond Roca

We will be sending a half pound bag of yummy homemade Almond Roca to our customer’s company buyers for any new purchase orders for production die casting parts and for die casting tooling purchase orders. PO’s received from now to the end of February qualify for the free candy. If you have never received our candy, now is the time to get some, by placing purchase orders you need to place anyway.

We did this February Almond Roca Special last year as well:

https://www.kineticdiecasting.com/kdc/end-of-february-almond-roca-special/