Today, we are reminding everyone that Kinetic Die Casting Company is on Facebook Take the time to go to our Facebook page and “Like Us” Our Facebook Page is updated every week with offers to get Homemade Almond Roca and …

Continue reading

Category Archives: Enclosures

Aluminum Enclosures 2019

What sensation aluminum has become in the hardware market is no secret. The metal and its derivatives are being widely being used in not only huge companies such as automobiles and aeronautics but also in small scale usage such as boxes and enclosures for mundane activities. Here is guide to the benefiting properties which make aluminum a favorite over its other metal and alloy counterparts, especially when it comes to boxes and enclosures. This article would also successfully hope to throw light on different purpose for which the boxes are being manufactured for.

DURABILITY

As of now, Aluminum is the most durable and its product the most stable, as compared to any other metal and its products if gauged on the scale of practical use. The aluminum boxes and enclosure, whether big or small are highly resistant to corrosive reactions and this one property is largely responsible for aluminum’s long life span.

PROTECTS THE STORED MATERIAL

Also, Aluminum alloy and the derivatives obtained from it have a very low reactivity when they come in contact with air. There may be many elements and metals which are much lighter and durable than aluminum but lose out because they react vigorously when kept in the atmosphere. These highly reactive metals cannot be used to make something for casual use like normal boxes. Aluminum, being low on reactivity protects the stored material inside form reactants and attacks from outside.

LIGHTER AND GOOD TEXTURE

Furthermore, Aluminum is very light as compared to other alloys/metals. This is one reason that huge enclosures which to be transported over long distances are made out of aluminum so that loading and unloading is a much easier task.

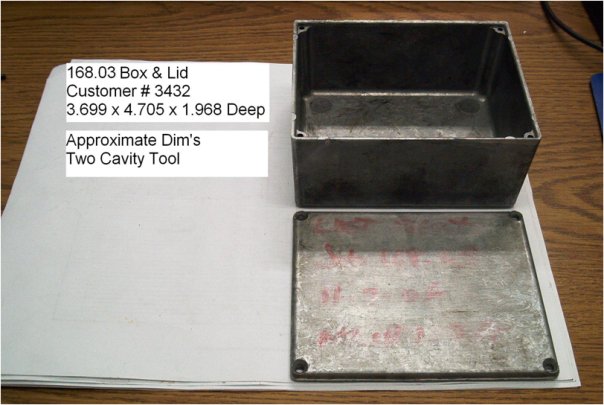

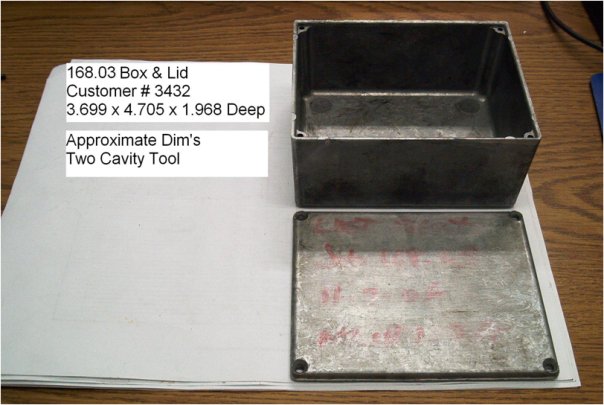

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Casting Boxes and Enclosure Die Castings

Die Casting Box Parts

Kinetic Die Casting Newsletter Articles

Die Casting Parts Draft Angle

Die Casting Box Pictures

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Box Prices

Kinetic Die Casting makes Aluminum Military Parts

Kinetic Die Casting Makes Aluminum Military Parts. The Kinetic Die Casting company provides its market with stronger than steel aluminum die cast parts. Kinetic Die Casting makes aluminum military parts as well as the wide range of products that you can avail from this company. If you are currently searching for military parts that are made of aluminum, you may want to limit your search for now with this company.

- There are cases wherein you have to get an overview of how much these kinds of products are being offered by different companies before you can limit your choices. In this case, the company is a strong one in the industry and you are assured not only with the quality but also with the kind of service that you also want to experience.

- This company is known to be a part die-caster of fairly priced aluminum die cast parts that have better quality than their competitors. These parts undergo a high pressure process of die casting. At this phase, molten aluminum alloy metal that is under pressure is being injected into steel die. The end result of this process is the aluminum parts. Die casting is less expensive when it comes to the processes of producing aluminum parts.

Contact Kinetic Die Casting Company to get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Kinetic Die Casting is located in Southern California. KDC specializes in aluminum and zinc die casting tooling. If you would like a quote, please visit our website:Kinetic Die Casting Company

Monitor Dynamics Die Castings

A customer of ours, in the early 1990’s, contacted Kinetic Die Casting Company, to send us their die casting tooling so we could produce an aluminum die casting enclosure housing for them. This company, Monitor Dynamics Incorporated (MDI), produced a security card reader system used in government buildings. MDI was well known for their high quality security systems. MDI demanded high quality products from their suppliers.

This aluminum die casting part had transformed many times from its inception. It started out as a steel box that was welded together. The design was simple, ¼ inch plates welded together in a box shape with a slot to slide electronic cards through and an area for a keypad. The next change was to make aluminum sand castings in a similar design. Later, the delivery and quantity requirements for the programs required MDI to purchase die casting tooling and die casting parts from a competitor of ours.

Unfortunately, our competitor did not realize the important differences between aluminum sand casting parts and aluminum die casting parts. The part design was poorly planned in the following ways:

- The draft on the interior walls was not properly created, the parts has several drag marks and stuck too easily in the tool.

- The tooling die not include a mold base, it consisted of inserts only. This kept the customer captive to the poor quality die casting company, our competitor.

- The wall thicknesses of 1/4” or more, “for higher strength”. Greater wall thicknesses in die casting parts for greater strength is a misconception.

Here is how I helped MDI get good quality parts. First, I had my toolmaker fix the internal draft angle problems so the aluminum housing parts would no longer stick in the die casting tool. Secondly, I mounted the inserts into one of our many available mold bases so we could make good quality die casting production parts.

Then finally, we fought the production process to make good parts in spite of the problems and complications from the ¼” or greater wall thicknesses. There were many complications, such as, several sink marks or surface porosity from the metal wicking from thinner areas of the casting to the thicker areas. The casting would deform easily in the cooling process. The internal porosity from the thicker sections would also cause the paint and powder coating to bubble.

MDI was very pleased with the results we provided them. Their purchasing manager sent me a letter of appreciation. MDI is now known as Ameritron, Incorporated. You can read a copy of the letter of appreciation from the purchasing manager here..

“In the 12 years, Kinetic Die Casting has been an excellent supplier providing good pricing, excellent product and on time delivery. If you have a need for die casting products I would highly recommend Kinetic Die Casting”

……. Read letter HERE

Contact Kinetic Die Casting Company 818-982-9200 if you have a difficult product to produce. We will be able to make parts for you when others fail. Send us your die casting tooling and we will make your parts for you. Kinetic Die Casting manufactures die casting metal parts creating products like roofing tile molds, lighting parts, and military parts. If you would like more information about Kinetic Die Casting, visit our website:Kinetic Die Casting Company

Permalink: https://www.kineticdiecasting.com/kdc/monitor-dynamics-die-castings/

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Enclosures Boxes Castings

Automotive Die Casting Parts

Die Casting Handle Hardware

Tooling for Die Casting

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Diecast Enclosures 2019

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum enclosures through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a steel die casting mold tool. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the enclosures are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Enclosures. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting parts every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Diecast Aluminum Housings

Aluminum Housing Castings or Aluminum Diecast Boxes are electrically conductive and can be easily be electrically grounded. Aluminum box enclosures can be manufactured with the mounting holes necessary for set up circuit boards and covers or lids to the enclosures to seal from humidity and damage to the components constructed. Die Casting Aluminum enclosures work well with die casting aluminum heatsink parts to remove and dispel heat from components.

Die Casting Aluminum Housings or Aluminum Diecast Boxes do not need welded seams, so they usually look better than other manufactured boxes. Depending on the size and weight of the parts, Aluminum cast boxes, aluminum diecast enclosures and aluminum housing castings made as die casting parts can be made at the rate of a few hundred to a few thousand parts each day. Aluminum Box Enclosures or Aluminum Box Housings Parts are easily powder coated.

Permalink: https://www.kineticdiecasting.com/kdc/diecast-aluminum-housings/

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Kinetic Die Casting manufactures custom metal parts to their customer. If you would like more information about Kinetic Die Casting, please visit our website:Kinetic Die Casting Company

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Enclosures Boxes Castings

Automotive Die Casting Parts

Die Casting Handle Hardware

Tooling for Die Casting

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877