Zinc Price Spike Sparks Flurry of Miner Listings A doubling in zinc prices since late 2015 and strong outlook for the commodity has fueled a flurry of zinc miner listings on the Toronto Stock Exchange as companies cash in on …

Continue reading

Category Archives: Enclosures

Why Aluminum Boxes?

Why Aluminum Boxes? To protect electronic machinery or components from the damages which water, moisture, dust, or abrupt shock can do, one has to use boxes which has the capability to keep the said factors away. This answers the question, “Why should you use Die Casting Aluminum Boxes?” It is because the die casting aluminum boxes can protect components from outside factors since they are made from aluminum die castings and also have die cast lids. The die cast covers can be bolted in place as a way of sealing the item. This will protect the components from factors which causes damages.

Why Aluminum Boxes? To protect electronic machinery or components from the damages which water, moisture, dust, or abrupt shock can do, one has to use boxes which has the capability to keep the said factors away. This answers the question, “Why should you use Die Casting Aluminum Boxes?” It is because the die casting aluminum boxes can protect components from outside factors since they are made from aluminum die castings and also have die cast lids. The die cast covers can be bolted in place as a way of sealing the item. This will protect the components from factors which causes damages.

Die cast aluminum boxes can also be utilized for RF/EMI shielding. This RF (Radio Frequency) or EMI (Electrical Magnetic Inductance) shielding is important if one wants to shield electronic components from unwanted interference which radio waves and frequencies can cause. Through the use of die casting aluminum boxes, electronic components are given RF/EMI shielding since the boxes have the capability of dispersing and absorbing any external frequencies. Utilization as enclosure for computer disk drives, computer components, engine compartments, motors, communication devices, electrical junction boxes, or car transmission is also one of the reasons why these boxes should be used. Since aluminum die cast parts are also less heavy than steel parts, as a manufacturer, it is more beneficial to use this. Aside from being electrically conductive, it will allow easier and less cost of transportation since it only weigh 1/3 of the weight of the steel parts.

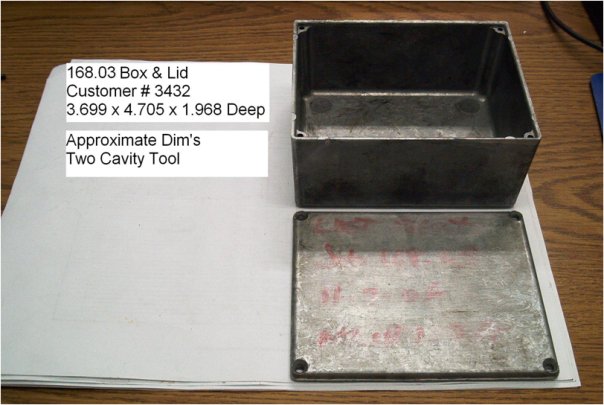

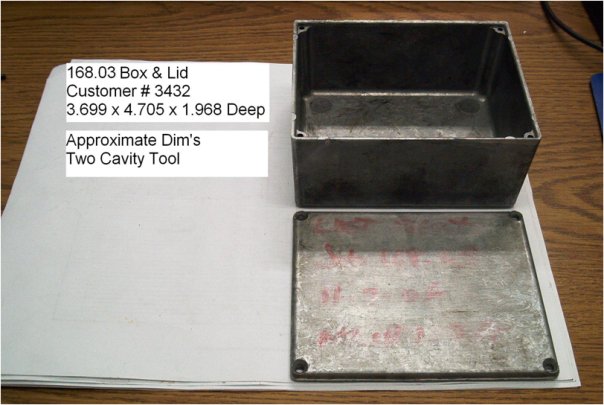

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

The Uses and Needs of Aluminum Boxes

Aluminum Boxes Uses and Needs. When it comes to storage options, most people prefer to go the plastic or wooden way since of the ease and convenience. But rising trends indicate that more people, especially the men are longing for metallic boxes more because of several factors that include strength and durability. An Aluminum box is the best when you are looking for durable storage. Aluminum has two qualities that make it the metal of choice. It is light and easy to work with, but it is also strong and very durable. In the world of storage and body building, that is a magic combination.

Aluminum Boxes Uses and Needs. When it comes to storage options, most people prefer to go the plastic or wooden way since of the ease and convenience. But rising trends indicate that more people, especially the men are longing for metallic boxes more because of several factors that include strength and durability. An Aluminum box is the best when you are looking for durable storage. Aluminum has two qualities that make it the metal of choice. It is light and easy to work with, but it is also strong and very durable. In the world of storage and body building, that is a magic combination.

There are different uses that you can put aluminum boxes into and it all depends on your intentions. Most of these are used in storing equipment when taking a road trips since they are strong enough to hold when things get a little bumpy. Some have taken to making these boxes large enough to make a little enclosure at the back of pick up trucks. Their workability is what makes aluminum the metal of choice. In the making of large transportation enclosures especially of animals, it is aluminum that is preferred. It does not add too much weight and that is the main reason whey it is chosen.

But when it comes to household settings, these boxes receive a fair share of attention too. Some are made small for storage of collections such as magazines and comic books. The aluminum boxes make for excellent storage since they protect the enclosed material from the elements for a couple of years. Besides, they are made rust proof which makes them more durable. For mailboxes, heavy duty or not, the aluminum boxes are excellent at carrying out the function with little flaw. One big advantage of using aluminum boxes is that they are good at taking sudden impact. Keeping away water, dust and moisture are other key advantages. If you want to store electronic components, you should use aluminum boxes since they keep away radio frequencies and Electromagnetic inductance. However to make sure that this is achieved there need be aluminum die casting so that the conductivity can work to your advantage.

Findings indicate that aluminum is about a third the weight of steel which means some boxes will be easy for you to carry. Aluminum boxes can be found with ease since there is availability of the metal in most places. They are not too expensive given their qualities. Besides, they are not easy to break into and that means that they are good at keeping thieves away. If an aluminum box was to be placed on the outside, away from shelter, it is able to withstand every kind of force that nature throws at it. In light with that, it is easy to understand why one would feel the obligation to get an aluminum box.

Next time you are out searching for a storage container or box, think aluminum and you can rest assured that you will not be disappointed.

Die Casting Aluminum Heat Sink Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Heat Sinks. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Enclosures

What sensation aluminum has become in the hardware market is no secret. The metal and its derivatives are being widely being used in not only huge companies such as automobiles and aeronautics but also in small scale usage such as boxes and enclosures for mundane activities. Here is guide to the benefiting properties which make aluminum a favorite over its other metal and alloy counterparts, especially when it comes to boxes and enclosures. This article would also successfully hope to throw light on different purpose for which the boxes are being manufactured for.

DURABILITY

As of now, Aluminum is the most durable and its product the most stable, as compared to any other metal and its products if gauged on the scale of practical use. The aluminum boxes and enclosure, whether big or small are highly resistant to corrosive reactions and this one property is largely responsible for aluminum’s long life span.

PROTECTS THE STORED MATERIAL

Also, Aluminum alloy and the derivatives obtained from it have a very low reactivity when they come in contact with air. There may be many elements and metals which are much lighter and durable than aluminum but lose out because they react vigorously when kept in the atmosphere. These highly reactive metals cannot be used to make something for casual use like normal boxes. Aluminum, being low on reactivity protects the stored material inside form reactants and attacks from outside.

LIGHTER AND GOOD TEXTURE

Furthermore, Aluminum is very light as compared to other alloys/metals. This is one reason that huge enclosures which to be transported over long distances are made out of aluminum so that loading and unloading is a much easier task.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Free Shipping

Free Shipping! Limited time offer. Hundreds of dollars in value, free to our customers. This offer is for parts from any manufacturing industry: Automotive Die Casting Parts, Airplane Die Casting Parts, Light Fixture Die Casting Parts, Aerospace Die Casting Parts, Military Die Casting Parts or Any Aluminum Die Casting Parts. New part? Die Casting Part Prices.

Kinetic Die Casting Company is giving away free shipping for die casting parts, on all new purchase orders. This is a limited time offer. Here is how you can save your manufacturing company money on aluminum die casting parts.

1. Send your purchase order to sales@kineticdc.com or fax 818-982-0877

2. Write on your purchase order “Free Shipping”

3. Call and confirm receipt of your purchase order 818-982-9200. Ask for Doris or Delmas.

4. You must be flexible with delivery of your parts between 1 and 4 weeks.

5. Offer good for all industry types of purchase orders, only the first week of June 2015.

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605 USA

Office Hours: Monday through Thursday 6:00 AM to 4:30 PM (Pacific Time)

Die Casting Part Prices

The Parts We Make Today, We Ship Today

Kinetic Die Casting Company makes aluminum die casting parts and zinc die casting parts for many manufacturing industries. We will make parts, machine the parts, powder coat the parts and ship the parts in 4 weeks or less, in most cases.