Die Casting Aluminum Car Parts in 2025. Automated aluminum car part die casting application using robots. For more information see the company’s website Kinetic Die Casting. After-market auto parts manufacturers depend on companies like Kinetic Die Casting to help with …

Continue reading

Category Archives: Tooling Die Casting

Aluminum Enclosures 2019

What sensation aluminum has become in the hardware market is no secret. The metal and its derivatives are being widely being used in not only huge companies such as automobiles and aeronautics but also in small scale usage such as boxes and enclosures for mundane activities. Here is guide to the benefiting properties which make aluminum a favorite over its other metal and alloy counterparts, especially when it comes to boxes and enclosures. This article would also successfully hope to throw light on different purpose for which the boxes are being manufactured for.

DURABILITY

As of now, Aluminum is the most durable and its product the most stable, as compared to any other metal and its products if gauged on the scale of practical use. The aluminum boxes and enclosure, whether big or small are highly resistant to corrosive reactions and this one property is largely responsible for aluminum’s long life span.

PROTECTS THE STORED MATERIAL

Also, Aluminum alloy and the derivatives obtained from it have a very low reactivity when they come in contact with air. There may be many elements and metals which are much lighter and durable than aluminum but lose out because they react vigorously when kept in the atmosphere. These highly reactive metals cannot be used to make something for casual use like normal boxes. Aluminum, being low on reactivity protects the stored material inside form reactants and attacks from outside.

LIGHTER AND GOOD TEXTURE

Furthermore, Aluminum is very light as compared to other alloys/metals. This is one reason that huge enclosures which to be transported over long distances are made out of aluminum so that loading and unloading is a much easier task.

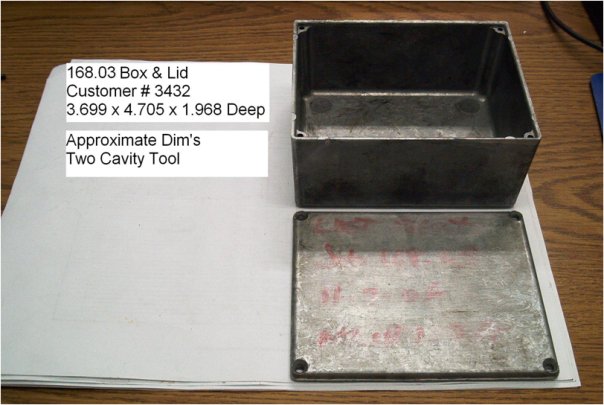

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Casting Boxes and Enclosure Die Castings

Die Casting Box Parts

Kinetic Die Casting Newsletter Articles

Die Casting Parts Draft Angle

Die Casting Box Pictures

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Box Prices

Die Casting Tooling Transfer 2019

Kinetic Die Casting Company will make die casting parts for our customers that send us their die casting tools from other die casting companies.

We are still offering a Die Casting Tooling Transfer special.

Manufacturing companies transfer their die casting tooling and we make their parts in just a few weeks.

Kinetic Die Casting Company, a better die casting part supplier.

Kinetic Die Casting Company makes that decision easier.

1. Send us your die casting tooling and die casting molds

2. A purchase order made to us with your old suppliers prices.

3. We will honor the die casting part price paid to the old die casting part supplier.

4. You will get better die casting parts than you received before.

5. We will ship the die casting parts to you in less than 4 weeks.

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605 USA

Office Hours: Monday through Thursday 6:00 AM to 4:30 PM (Pacific Time)

818-982-9200 – sales@kineticdc.com – www.kineticdiecasting.com

Permalink: https://www.kineticdiecasting.com/kdc/die-casting-tooling-transfer-2019/

Die Casting Tooling and Die Casting Molds

Die Casting Tooling Information

Tooling Used in Die Casting

Frequently Asked Die Casting Questions

Die Casting Tile Molds

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Tooling Prices

Multiple Cavity Tooling

When our customers buy die casting tooling, they have an option to buy single or multiple cavity tools. In die casting, we are limited in the number of parts we make in a die casting shot. “Shot” refers to a single event in the die casting production shot cycle. The die casting shot cycle is: Die Open, Spray, Die Close, Inject Metal, Open Die, Eject Part and Repeat (More in another article). A shot takes about a minute. With a single cavity tool, we make one part each shot, or one part a minute or 60 parts an hour. If our die casting tool has more than one cavity, we make the proportionate number of parts. A two cavity, multiple cavity die casting tool produces 120 parts an hour and four cavity die cast tooling produces 240 parts an hour.

The more parts we can produce in an hour, the lower the labor cost in the die casting part price. Part prices are lower with a multiple cavity tool.

- Review my other articles on Die Casting Tooling:

- Complete Molds, Complete Die Casting Dies

- Die Casting Unit Die Tools (DME)

- Die Casting Cavity Inserts “Tooling Inserts”

- Die Casting Trim Dies

Permalink: https://www.kineticdiecasting.com/kdc/multiple-cavity-tooling/

“The Parts We Make Today, We Ship Today”

What Are Die Casting Parts?

Die Casting Tooling Prices

Die Casting Tooling

Kinetic Die Casting Company

6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Diecasting Tooling Transfer

Kinetic Die Casting Company uses die casting tooling and die casting molds to make die casting parts for our customers. Some customers send us tooling that was used by other die casting companies to make parts and we will make these aluminum or zinc parts for our customer.

Kinetic Die Casting is offering a Die Casting Tooling Transfer special.

Manufacturing companies can transfer their die casting tooling to Kinetic Die Casting Company and we will make their aluminum or zinc parts in just a few weeks.

Kinetic Die Casting Company, a better die casting part supplier. We make that decision easier.

1. Send us your die casting tooling and die casting molds

2. Send us a purchase order made to us with your old suppliers part prices.

3. We will honor the die casting part price paid to the old die casting part supplier.

4. You will get better die casting parts than you received before.

5. We will ship the die casting parts to you fast.

Permalink: https://www.kineticdiecasting.com/kdc/diecasting-tooling-transfer/

Quote Die Casting Part Prices

Die Casting Prices

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

What is Die Casting

Die Casting Part Pictures

Diecast Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Lighting Fixtures

Die Casting Lighting Fixtures. In any house, building and other man made structure that is covered or in the dark, it will need artificial lighting so that it becomes hospitable and safe. Both outdoor and indoor lighting is essential in any place where people reside because people rely on light to get things done. For those which don’t receive any natural lighting, Aluminum Lighting Fixtures are the solution to this problem. Most, if not all housing and buildings make use of this feature and aluminum is a great choice for this because it is light in weight so that it can easily be installed or replaced and at the same time, it is durable so it will last longer.

Of course, Aluminum Lighting Fixtures should be made in vast quantities at a time because structures, especially buildings, would require a lot of these artificial lighting equipment. To achieve this, the best method in creating lighting fixtures is with die casting. This process can turn the aluminum into the finished product in no time as the metal is melted and using molds and castings, can be structured into the proper shapes and sizes.

When it comes to Aluminum Lighting Fixtures, die casting is the cheapest, most reliable way to achieve high quality results. And since this method makes use of the same mold, the resulting products are always consistent when it comes to the dimensions and the quality. Fast and efficient, die casting has become very popular not only with making Aluminum Lighting Fixtures, but with other parts as well.

Permalink: https://www.kineticdiecasting.com/kdc/die-casting-lighting-fixtures/

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

What Are Die Casting Parts

How Much Are Die Casting Part Prices

What Is Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877