The Advantages of Cast Aluminum Parts for Music over Plastic Parts. For serious musicians and the musical professionals in the music industry, having instruments that last longer, that sound extraordinarily good, and that are strong and sturdy is very important. …

Continue reading

Art Mold Die Casting is Closed

Sadly, one of our competitors has closed their operations. Another California Die Casting Manufacturing Company is gone.

Art Mold Die Casting Company 11872 Sheldon Street Sun Valley, CA 91352 is closed. ArtMold started producing die castings in 1978. Nearly 40 years in business here in Southern California. Their commitment to excellence and concern for competitive pricing was an integral part of their growth. Sadly, their demise came at the hands of foreign competitors. They could no longer maintain their high standards of quality while paying increased costs for doing business in California. Art Mold still tried to compete with die casting prices from countries that do not have a minimum wage law, competitors that do not pay insurance costs, they do not pay holiday pay for employees or pay employees for sick days.

Now about my company, Kinetic Die Casting Company.

We are still going strong. My company does an excellent job taking care of my employees with fair wages, paid vacations, paid sick days, and holiday pay. In return, my customers get excellent service, the best product quality and the willingness of my employees to deliver products on time. A small price to pay for world class results. As a small American manufacturer, I keep my product prices as low as possible to compete globally. I work with customers by giving them discounts on prices whenever I can. We are local, customers can order and get products in one or two days. We are willing to produce low production quantities of parts. Our quality is the best quality you can find. We are available by email or phone at any time. We have no hidden environmental fees or setup fees. We expedite our products for free if our customers make a mistake logistically. I am helping the local economy by keeping manufacturing jobs here in California.

Yes, we are taking over some of the die casting work from ArtMold Die Casting Company (AMDC). We are 15 minutes away from AMDC. I have agreed with the owner of AMDC that I will honor the prices they have with their existing customers. He also agreed to give me any special tips necessary to make your parts.

Our Motto: “The Parts We Make Today, We Ship Today” Kinetic Die Casting Company was founded in 1994. (www.kineticdc.com)

We produce production parts for many industries:

• Aerospace,

• Automotive,

• Electrical Connectors,

• Lighting,

• Military and

• Commercial.

Here are a few links to a few pictures:

– Aerospace parts http://www.kineticdiecasting.com/aerospace_part_pictures.html

–

– Enclosures and housing parts http://www.kineticdiecasting.com/enclosure_part_pictures.html

We are happy to produce any quantity of production parts, we typically make about 500 parts a day. Some customers order as few as 100 parts. We also have customers that order over 100,000 parts a year. We make parts from as small as 1/8” weighing .001 pounds to as large as 17” and weighing 10 pounds. Our deliveries are typically less than 6 weeks. Please call us if you have specific questions.

Kinetic Die Casting Company

6918 Beck Avenue North Hollywood, California USA 91605

818-982-9200

sales@kineticdc.com

Permalink: https://www.kineticdiecasting.com/kdc/art-mold-die-casting-is-closed/

Art Mold Die Casting Company is Closed

How to Use Aluminum Aircraft Parts?

How to Use Aluminum Aircraft parts. The popular aircraft airframe has been the most challenging function for aluminum alloys; to account the progress of the high strength alloys is as well to account the progress of airframes. Duralumin is the first high strength, high temperature treatable aluminum alloy and was utilized originally for the structure of stiff airships. Duralumin was actually an aluminum-copper-magnesium alloy. It was initiated in the country of Germany and expanded in the United States of America as alloy 17S-T. It was employed first and foremost as a sheet and plate.

How to Use Aluminum Aircraft parts. The popular aircraft airframe has been the most challenging function for aluminum alloys; to account the progress of the high strength alloys is as well to account the progress of airframes. Duralumin is the first high strength, high temperature treatable aluminum alloy and was utilized originally for the structure of stiff airships. Duralumin was actually an aluminum-copper-magnesium alloy. It was initiated in the country of Germany and expanded in the United States of America as alloy 17S-T. It was employed first and foremost as a sheet and plate.

Throughout the 20th century, aluminum turned out to be an important metal in aircraft. The cylinder mass of the engine that controlled the plane of the famous Wright brothers at Kitty Hawk in 1903 was a one piece die casting in an aluminum alloy consisting of 8% copper. The aluminum propeller blades emerged as early as 1907 and aluminum seats, covers, cast brackets, cowlings, and comparable parts were regular by the start of the World War I.

In the year 1916, L. Brequet created a scouting bomber that identified the primary utilization of aluminum in the functioning configuration of a plane. By the end of the war, Germany and the Allies used aluminum alloys intended for the constructional scaffolding of fuselage and section assemblies.

Kinetic Die Casting Company makes aluminum die castings as Airplane Die Castings. We make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Happy 4th of July 2016 from Kinetic Die Casting Company

Happy 4th of July 2016 from Kinetic Die Casting Company.

We are closed Monday, July 4th in celebration of our nations independence. God Bless America. We hope that your first half of the year was prosperous and also hope that you year continues to be prosperous.

God Bless America 2016

Take a look at our Face Book page and click like:

Like Us

![]()

http://www.facebook.com/kineticdc

Kinetic Die Casting manufactures products like:

If you would like more information on Kinetic Die Casting, please visit our website:

http://www.kineticdiecasting.com/

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

818-982-9200

sales@kineticdc.com

The Aluminum Lighting Parts vs. Steel

The Aluminum Lighting Parts vs. Steel. Aluminum and steel are metals that have been the best choices for lighting parts. They’re both durable and readily available in the market. However, in this article, you will find out why choosing aluminum is better.

The Aluminum Lighting Parts vs. Steel. Aluminum and steel are metals that have been the best choices for lighting parts. They’re both durable and readily available in the market. However, in this article, you will find out why choosing aluminum is better.

First of all, it is easier to modify an aluminum product than a steel product. A set of simple tools is enough to cut, sharpen and weld aluminum. Changing a lighting part made of aluminum would take less time and effort than having a lighting part made of steel, which is harder to alter.

Furthermore, Lighting parts made of steel are also considerably heavier than the ones made of aluminum die casting, adding more weight to the car. This may sound like a good thing, but an extra weight will make steering a bit difficult.

Also, broken aluminum lighting parts can be sold at a higher price than the ones made from steel.

An aluminum lighting part needs not to be painted unlike a steel one to prevent it from rusting. It will also not require a re-painting job once the paint smudges off. This will help you cut back on expenses.

The advantages of aluminum lighting parts over steel listed in this article should help one in deciding what to buy and what not to buy.

Light Fixture Die Casting Parts

Kinetic Die Casting Company makes aluminum die castings as Lighting Fixture Die Castings. We make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

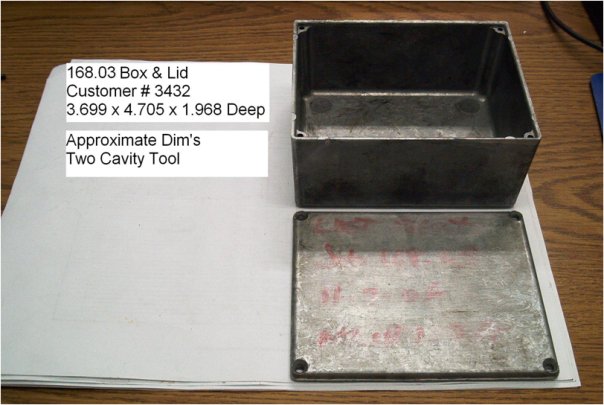

Die Casting Aluminum Boxes made by Kinetic Die Casting Company

Die Casting Aluminum Boxes made by Kinetic Die Casting Company. If you are looking for boxes which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 15 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Boxes made by Kinetic Die Casting Company. If you are looking for boxes which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 15 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum boxes through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a die cast or steel die cast mold. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the boxes are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com