Do you know someone that can use our rapid production die casting services? Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605 www.kineticdc.com #diecasting #kineticdc #manufacturing #production @kineticdc Does anyone need fast die casting production? Call us and …

Continue reading

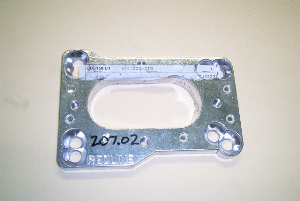

Die Casting machine

Kinetic Die Casting company uses die casting machines to make parts

Automotive Parts Made with Zinc Die Castings

Useful Information about Die Casting Zinc Automobile Parts. Manufacturing automobiles normally include die casting zinc automobile parts. An automobile is composed of thousands of parts, countless of which are manufactured from zinc. Zinc may also be joined with other alloys to attain detailed purposes. There are useful reasons why die castings is done for manufacturing cars and other four-wheeled vehicle parts:

• Cars are mass manufactured and need many mechanisms; die casting is a fast yet dependable technique to generate metallic parts for them

• Die casting is multipurpose and has the prospective to make parts in changeable shapes and sizes

• The subsequent goods are sturdy and very long-lasting

• It’s inexpensive to die cast car parts likened to other forms of production

• Die casts are readily recyclable and non-toxic

Zinc is an outstanding choice of alloy for constructing auto parts because it is unbending, hard, small, lightweight, non-sparking, and not corrosive. The bulk of vehicles have zinc parts in them because they perform well and are low-priced to produce. Here are some uses of die casting zinc automobile parts:

• For shielding electronic components

• For enclosing airbags, sensors, telematics, switches, and other sensitive equipment

• For constructing solid items, such as lock barrels, seat belts, etc.

• For ornamental purposes – metal platings, finishes, and designs

Though die casting zinc automobile parts is an acclaimed procedure, the quality shaped still be contingent on what the manufacturer does. When buying auto parts, search for a die caster with a decent track record of creating quality parts that have passed difficult testing.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

Kinetic Die Casting Products

Kinetic Die Casting Company produces many products for manufacturing companies. Many of the products are used every day and can be seen every day. One product that is used frequently is the Utility Knife also known as a Box Cutter.

This metal box cutter is made using the aluminum die casting process. The aluminum die cast handles provide strength and stability as well as the weight of a metal knife handle. Kinetic Die Casting Company has been making these metal box cutters for several years. Contact us if you are interested in buying one of these beautiful products.

Kinetic Die Casting Company 800-524-8083

Zinc Die Casting and Its Use on Tools

Zinc Die Casting and Its Use on Tools. Hardware parts are chiefly made of metal. It is the most common material used for the production of tools because of its strength and robustness. Repairs, after all, need fortitude not only from the wielder of the tool but from the tool itself. A flexible screwdriver, after all, is not good in execution of its function if it is made of inferior material.

One process of manufacturing tools and other metal parts is zinc die casting. Hardware parts such as wrenches, electrical connectors, gearbox and turbine housings, and locks can be made out of zinc. This metal is a decent foundation of raw material because it shows characteristics that are primary in the mind of an astute customer: strength, ductility, and durability.

The strength, ductility, and durability alone are enough to persuade any person to change to materials made from zinc die casting. Zinc hardware parts made from zinc are assured to be durable, able to endure strong impacts from hammering, screwing, and bolting.

Apart from tools, zinc is also used in the construction of wires, parts of appliances and laptops, lights, aircrafts, and other objects. It can be used in various products because of its flexibility and endurance.

Construction and repair are two activities that need dependence on human forte as well as tools. It is but appropriate that the tools used in these activities match the stress and pressure essential by the jobs. Objects made of zinc may just be the best match for people who are looking for such.

This is the blog on the Kinetic Die Casting Company web site. We make several types of Aluminum Handle Parts. Look at this website page for more details: www.kineticdiecasting.com/handle.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

Why People Use Aluminum Die Castings

Why People Use Aluminum Die Castings. Die casting is a powerful manufacturing process which involves the production of geometrically complex parts made from reusable molds, which is called die. The process of die casting involves the use of metal, a hot furnace, casting machinery and several pieces of die. The metal used, typically a non-ferrous type of alloys such as zinc or aluminum, is melted in the furnace and then injected to the casting machine. There are actually types of machines used in this process, there is the hot chamber die casting machine, used in zinc, and low melting temperature metals and there is the cold chamber machine which is used in aluminum and with high melting temperature type of metals. Both machines have the ability to rapidly cool and solidify the final part of the metal, which is called the casting.

People utilize aluminum in die casting because of its properties. Aluminum is lightweight and has powerful dimensional stability and changeability. This means that the metal can be used in order to create complex shapes and thin sheets of walls. Aluminum also has a good corrosion value and strong mechanical properties. Along the lines of its strength, aluminum also has high electrical and thermal conductivity, making it effective in various electronic projects. This metal can also be used and mixed with other types of metal in order to create stronger types of alloy for other types of projects. Even though aluminum is exposed to electricity and high temperatures, it still retains strength and that is why people utilize aluminum in die casting.

This is the blog on the Kinetic Die Casting Company web site. We make several types of Aluminum Handle Parts. Look at this website page for more details: www.kineticdiecasting.com/handle.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html