A few years ago I received a phone call from Scott. He had developed a Chocolate Fountain that is the best on the market. Being a diecaster, I did not know what a chocolate fountain is and what a hit …

Continue reading

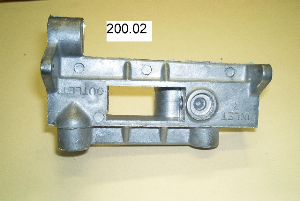

Aluminum Bracket Diecastings

Brackets are used for mounting electronic devices. Electronic devices are usually fragile and need a single fall before being permanently damaged like aluminum guitar amplifiers. Another problem is that many of these items are usually mounted onto walls to save space and to increase their output. A good method to solve this problem is by simply putting these items on top of other surfaces. However, this reduces the quality of their output. The best solution is to purchase aluminum brackets to safely secure the electronic items on the wall.

Aluminum brackets are L-shaped pieces of metal that are used in pairs to make a surface for mounting electronics. These are oftentimes used in mounting speakers and other sound related electronics. The more recent application for this item is the mounting of computer monitors and flat screen televisions onto the wall. The variety of brackets that are used for this purpose have a swivel feature which allows the user to adjust the screen.

When purchasing aluminum brackets, it is important to first determine the product on which the bracket would be used on. This would dictate the type of bracket that could be used, the weight carrying capacity of the bracket, and the features that could be present in the bracket. Although this may seem as a hindrance for most people, it actually is not. Brackets are usually labelled with the products that they are compatible with so that customers do not have to bring their electronic items along with them. Also, brackets may come with the package of the electronic item being purchased making it redundant to purchase brackets in the first place.

This is the blog on the Kinetic Die Casting Company web site. We are an American Die Casting Company. Look at this website page for more details: www.kineticdiecasting.com/american_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

Heatsinks Faster and Cheaper

Heatsinks are important in all electronic products or applications because they remove the heat to avoid overheating and malfunctions. These aluminum heatsinks are designed in such a way that the heat coming from the electrical component parts that are prone to heat production will be transferred to them. Since heat sinks are very important in many electronic products, manufacturers are designing cheaper and faster ways to produce them. One of the popular materials used in heat sinks is aluminum and these heat sinks are die casted in aluminum.

Aluminum is a strong metal that is perfect in making heat sinks. It is also easy to mold but very durable and can withstand high temperatures. The abundance of aluminum also makes it possible to produce cheaper products as compared to other metals. Die-casting is one of the best ways to make heat sinks. With diecasting, detailed heat sinks are produced in a short period of time, thus mass production is possible. Once heat sinks are produced, they are just mounted on the printed circuit board or the PC board of the electronic products. With this, the diversion of heat is now possible so as to prevent malfunction and can lead to longer lifespan of the application.

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Permalink: https://www.kineticdiecasting.com/kdc/heatsinks-faster-and-cheaper/

NADCA West Coast 2018

North America Die Casting Association NADCA is excited to announce the West Coast California Die Casting Congress on January 11-12, 2018 at the Hilton Long Beach. The Congress will feature technology highlights of our Congress in Atlanta last year in fall. It is important to use that all our members are able to access this information prevalent to the advancement in the industry. The event will kick off with a cocktail reception on January 11 and lead into a full day of presentations on January 12.

The NADCA Die Casting Congress will be sponsored by a limited number of Die Casting Suppliers that attendees will be able to meet with to learn more about products and services available to the die casting industry.

The cost is just $20 for NADCA Members and $50 for Non-Members*. Contact Melisa Ryzner, CMP 847-808-3161 Education & Meetings Manager. If you are sending more than 5 people you can receive discounted pricing.

Thursday, January 11, 2018

Cocktail Reception 5:30 – 7:00 pm

Friday, January 12, 2018

Breakfast 7:30 – 8:30 am

Congress Presentations 8:30 am – 4:30 pm

Lunch 11:45-1:15 PM

Die Casting Congress West

Long Beach, CA

January 11-12, 2018

Hilton Long Beach

701 W Ocean Blvd

Long Beach, CA 90831

Event Rate:

$20 NADCA Members

$50 Non-Members

Contact Melisa Ryzner, CMP 847-808-3161

*Registration includes access to the cocktail hour as well as breakfast and lunch on January 12.

Permalink: https://www.kineticdiecasting.com/kdc/nadca-west-coast-2018/

2018 Aerospace Die Casting Parts

Did you know that Kinetic Die Casting Company makes Aerospace Die Casting Parts? We do!.

Kinetic Die Casting Company makes parts that are used for aircraft lights, airplane motor, aircraft cargo systems, aerospace electronics, and aerospace fueling systems.

Kinetic Die Casting Company manufactures several aerospace die casting parts of many types and sizes. Aerospace die casting parts are purchased from Kinetic Die Casting Company by aerospace manufacturing companies. The list of aerospace companies that uses parts that Kinetic Die Casting produced is very impressive.

Aerospace Parts as die castings

Here is a list of a few of our Die Casting Aerospace Parts customers:

https://www.kineticdiecasting.com/kdc/die-casting-aerospace-parts/

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

For die casting prices, click here:

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Diecast Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling Molds

Permalink: https://www.kineticdiecasting.com/kdc/2018-aerospace-die-casting-parts/