Die Casting Job References. Upon making your resume, it is typical to add a list of names at the last part, which will serve as your die casting jobs references. You can also type it on a different sheet of …

Continue reading

Tag Archives: Aircraft Parts

Airplane Bracket Castings

Spotting Bracket Die Castings in several very different locations is interesting. While I was traveling in a Boeing 747-700 Airplane I discovered that the “Seat-Back Tray-Table” is held up using by two aluminum die casting parts as Bracket Castings. These bracket castings were attached to the seat back of the seat in front and to a plastic tray table. These aluminum bracket die castings are painted white to match their surroundings. These aluminum brackets are strong enough to hold a laptop or a plate of food or even the hands of someone working a puzzle or a book. These brackets are strong because they are designed using geometry that gives the bracket casting strength with corner radii and ribs and gussets.

Aluminum Die Casting Airplane Parts are very common. Most airplanes are made from aluminum as the metal of choice. Aluminum die castings are lightweight and strong.

Bracket Castings on Boeing 747-700 Airplane

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

2018 Aerospace Die Casting Parts

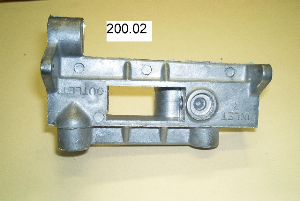

Did you know that Kinetic Die Casting Company makes Aerospace Die Casting Parts? We do!.

Kinetic Die Casting Company makes parts that are used for aircraft lights, airplane motor, aircraft cargo systems, aerospace electronics, and aerospace fueling systems.

Kinetic Die Casting Company manufactures several aerospace die casting parts of many types and sizes. Aerospace die casting parts are purchased from Kinetic Die Casting Company by aerospace manufacturing companies. The list of aerospace companies that uses parts that Kinetic Die Casting produced is very impressive.

Aerospace Parts as die castings

Here is a list of a few of our Die Casting Aerospace Parts customers:

https://www.kineticdiecasting.com/kdc/die-casting-aerospace-parts/

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

For die casting prices, click here:

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Diecast Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling Molds

Permalink: https://www.kineticdiecasting.com/kdc/2018-aerospace-die-casting-parts/

Diecastings Made 2017

Kinetic Die Casting Part Types in 2017:

Die Casting Military Parts.

Die Cast Heater Plates.

Aluminum Heat Sinks Die Castings.

Golfing Products.

Cast Aluminum Golf Products.

Aluminum Handle Hardware.

Aluminum Chassis Castings.

Cast Aluminum Parts for Music.

Aluminum Hardware Brackets.

Aluminum Automotive Parts.

Cast Aluminum Lighting Parts.

Aluminum Lighting Fixture Parts.

Aluminum Speaker Parts.

Roofing Tilemolds.

Cast Aluminum Rooftile Molds.

Aerospace Die Castings.

Cast Aluminum Boxes.

Aluminum Aircraft Parts.

Die Casting Company.

Images Pictures Die Cast Parts.

Answers for Diecastings.

Kinetic Die Casting Company Blog.

Die Casting Tools Molds .

Kinetic Die Casting Company.

Permalink: https://www.kineticdiecasting.com/kdc/diecastings-made-2017/

Low Quantity Diecastings

Low Production Die Castings Cost. Heating plates are mostly seen in the home and in laboratory equipment that need continuous heating or source of heat like chocolate fountains. Many manufacturers prefer producing heating plates using aluminum alloy because this alloy has thermal properties that are suitable to play the role of heating plates. Many manufacturers also use die casting in producing heating plates because they find it more convenient and economical to use as compared to other processes.

In die casting, aluminum is melted by exposing to extremely high temperature. When the metal is already melted, it will be injected in molds or dies to take the shape of the parts. Afterward, when the metal is already solidified, the parts or casts in the dies will be removed and will be slightly polished. The parts are near net shape, meaning they are produced as whole parts so joints will be avoided. This makes the pressure die casting more efficient because it produces stronger and more durable products unlike other processes like extrusion. In extrusion, the products produced are in cross section making the parts less durable as compared to die casting. Aside from this, heating plates do not need hollow parts like that of what will be produced in extrusion. Lastly, pressure die casting is much inexpensive than extrusion that is why many manufacturers use die casting instead of extrusion.

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Permalink: https://www.kineticdiecasting.com/kdc/low-quantity-diecastings/

Kinetic Die Casting manufactures zinc and aluminium die casting. If you would like a quote, please visit our website:

Die Casting price quote

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

2017 Limitations for Kinetic Die Casting Company

Here is the basic limitations of buying die casting parts from Kinetic Die Casting Company

Aluminum Die Casting Alloys (90% of our business)

A360 aluminum (Mostly used for Automotive and Lighting including low copper A360)

A380 aluminum (Most common alloy) Including A383 and A384

A413 aluminum (Mostly used in Aircraft, Heat sinks and Lighting)

Zinc Die Casting Alloys – Cold Chamber (10% of our business)

ZA27 Zinc-Aluminum die casting alloy

#3 Zinc (ZAMAK 3) Most common zinc die casting alloy.

#5 Zinc (ZAMAK 5)

Die Casting Part Sizes and Die Casting Part Weights we have made:

Smallest part we have made is 0.25 inches by 0.25 inches for BK Lighting Company weighing a few grams

Largest part we have made is 17 inches by 14 inches for Pioneer Roofing Tile Company weighing 8 pounds.

Die Casting Production Quantity:

Lowest quantity of parts shipped to Parker-Hannifin Corp. FSD of ten (10) parts on purchase order.

Highest quantity of parts shipped for pump housings of over 450,000 parts in a year.

Production Parts Delivery:

Purchase Order (PO) receipt to production shipment in less than 4 weeks.

Expedite to less than a week is possible.

Transfer tool to KDC for production in 4 weeks or less is typical.

Kinetic Die Casting Production Part Types:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Permalink: https://www.kineticdiecasting.com/kdc/2017-limitations-for-kinetic-die-casting-company