Maximizing Roof Tiles Production with New Roofing Tile molds. Aluminum is a kind of metal that has a long history of utilization in the construction industry. Several roofing firms have found out that aluminum provides a good material for tile …

Continue reading

Tag Archives: Aluminum Die Casting Company

Kineticdc is Looking for Die Casting People

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 is looking for Die Casting People to operate die casting machines. We have other Die Casting Jobs are available. A die casting machine operator must be able to efficiently operate a die casting machine to make good quality die casting parts. The die casting machine operator should be able to make adjustments to the die casting machine to improve the quality and efficiency of the die casting parts produced in their machine. We have other die casting jobs available.

Die Casting Job Skills and Job Abilities

* Must have experience operating an aluminum die casting machine.

* Be able to make adjustments to the die casting machine to improve quality.

* Be able to make adjustments to the die casting machine to improve efficiency.

* Willing to learn to set dies in die casting machine.

* Willing to learn to set trim dies in trim press.

* Must be willing to work as a team member.

* Must also be willing to assist and train other team members.

* Must be able to speak and read English.

* Must be willing to work any shift.

* Must be willing to work overtime.

* Must have reliable transportation to Kinetic Die Casting Company.

* Die casting mold setup experience is a plus.

* Forklift experience is a plus.

Die Casting Job Salary and Benefits

* This is a position with growth opportunity.

* Compensation $12 – $18 per hour, possibly more is based on die casting experience and skills.

To set up an die casting job interview.

- Click on the Online Job Application Button to complete our employment application online for position at Kinetic Die Casting Company.

- Send completed Job Application, Resume and Salary History to Kinetic Die Casting Company for a Die Casting Job Interview.

Send: Completed Job Application, Full Work Resume and Salary History

Fax: 818-982-0877 or Email: job@kineticdc.com or

* Mail to:

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood Ca. 91605

Call to set up a job interview.==> 818-982-9200 <==

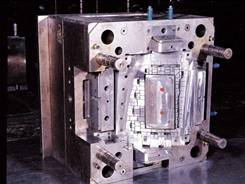

Die Casting Tooling Inserts

Die Casting Tooling Inserts. There are four types of die cast tools. These are: the single cavity die, the multiple cavity die, the unit die and the combination die. However, all of these dies may have one thing in common. These may be using smaller pieces of metals called inserts. With the advancement in the designing process, many of the more sophisticated die casting tooling can now be fabricated successfully using these smaller pieces of metal. Although these may look nothing more than thin rods of material or even a blob of metal (literally) inserted in the die, inserts are probably the best and most economical way of creating sophisticated cast die pieces.

Die Casting Tooling Inserts. There are four types of die cast tools. These are: the single cavity die, the multiple cavity die, the unit die and the combination die. However, all of these dies may have one thing in common. These may be using smaller pieces of metals called inserts. With the advancement in the designing process, many of the more sophisticated die casting tooling can now be fabricated successfully using these smaller pieces of metal. Although these may look nothing more than thin rods of material or even a blob of metal (literally) inserted in the die, inserts are probably the best and most economical way of creating sophisticated cast die pieces.

The main purpose of inserts is to create the holes or the running tubes within the piece. In earlier times, these holes or tubes can only be “placed” within a finished piece by manually or mechanically gouging it out. Needless to say, this can be a pricey affair especially if you consider the actual cost of hiring either skilled workmen to drill the holes or buying machines for the same purpose. Also this practice was subject to a lot of errors and therefore not feasible for mass production – especially when quality control is very rigid.

Fortunately, die cast tooling inserts can now be easily accommodated in most cast die machines. The material used for inserts depend on the actual materials being processed by the machines. As a rule hot chamber machines use molten materials with lower melting points like copper, lead, magnesium and even zinc. On the other hand, cold chamber machines use mainly aluminum or aluminum based alloys which have higher melting points. The inserts are made from the same materials as the actual die, usually steel alloys, but these are reinforced to make sure that metal erosion does not take place during the actual production stage.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Myths of Groundhogs and Economics

Happy Groundhog Day.

This is a traditional holiday celebrated each year on February 2nd. Groundhog day was used to forecast the winter weather. According to folklore, if it is cloudy when a groundhog emerges from its burrow on this day, then spring will come early; if it is sunny, the groundhog will supposedly see its shadow and retreat back into its burrow, and the winter weather will persist for six more weeks. This fun tradition does not accurately predict the weather, but fun, all the same.

Economic forecasting is also a highly-imperfect exercise. The Dow Jones Industrial Average (stock market) has dropped significantly the past few weeks. Based on other recent economic data, we do not believe either the global or U.S. economies will fall into recession. There are many recession indicators available. All these indicators have varying degrees of historical reliability. The bulk of these indicators indicate less than a 50% chance of a U.S. recession. Globally, in 2016, we will see continued growth in Europe and only a modest deceleration in China, while other indicators are at levels associated with a low probability of global recession.

Our customers, all of them manufacturers, are on the leading edge of any change in our economy. Most of our customers are preparing for growth rather than recession in 2016. Kinetic Die Casting Company is preparing and we are taking steps to handle the growth we expect to see in 2016.

Contact us today to get your die casting production order in our schedule. Click here for a die casting part price http://www.kineticdiecasting.com/replyform.html

Myths of Groundhog shadows and Economic Indicators

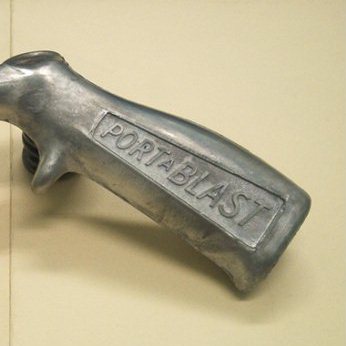

Worldwide Used Consumer Die Castings

Worldwide Used Consumer Die Casting. For the business of manufacturing bulk orders of parts made from non ferrous metals such as tin, zinc, copper or the most popular of them all, aluminum. Aluminum has become very popular in Consumer Parts Die Castings because of its unique properties. It is one of the most sought after metal alloys in the world and at the same time, it is very easy to find. It can be mined of the top of the earth by grinding ores. They are known to be as hard, as tough and as strong as steel, however aluminum is just a third of the weight of steel of the same size, making it an even better choice for some manufacturers of Consumer Parts Die Castings. But, how exactly is die casting accomplished?

Worldwide Used Consumer Die Casting. For the business of manufacturing bulk orders of parts made from non ferrous metals such as tin, zinc, copper or the most popular of them all, aluminum. Aluminum has become very popular in Consumer Parts Die Castings because of its unique properties. It is one of the most sought after metal alloys in the world and at the same time, it is very easy to find. It can be mined of the top of the earth by grinding ores. They are known to be as hard, as tough and as strong as steel, however aluminum is just a third of the weight of steel of the same size, making it an even better choice for some manufacturers of Consumer Parts Die Castings. But, how exactly is die casting accomplished?

Also, die casting is similar in many ways to another manufacturing business process known as permanent mold casting, wherein the material that is to be used to create the parts are first liquefied by exposing it in extreme temperatures. When the material becomes liquid, it will be poured into molds. In permanent die cast mold casting, after the liquid material has been poured into the molds it will be allowed to cool and harden, in die casting the molds are subjected to high amounts of pressure first to ensure that the material gets into every nook and cranny of the mold. In this way, Consumer Parts Die Castings give better and more accurate results compared to any other manufacturing process to create small or medium sized parts.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Support from Aluminum Brackets Hardware

Get absolute support from aluminum brackets hardware. Structural integrity is a foremost consideration among architects and engineers in constructing homes and buildings. Aluminum brackets hardware has therefore become a major component in the construction of houses, buildings and other structures. Through the metallurgical process of die casting, the advantages of constructing with aluminum materials have been brought to the fore, leading to the development of various types of brackets such as the multi-purpose servo bracket and angle bracket.

Get absolute support from aluminum brackets hardware. Structural integrity is a foremost consideration among architects and engineers in constructing homes and buildings. Aluminum brackets hardware has therefore become a major component in the construction of houses, buildings and other structures. Through the metallurgical process of die casting, the advantages of constructing with aluminum materials have been brought to the fore, leading to the development of various types of brackets such as the multi-purpose servo bracket and angle bracket.

Construction cost can be considerably reduced using aluminum brackets hardware which is cheaper to mass-produce through die-casting. This process involves pouring molten aluminum into molds that could be designed into specifically designed shapes or cavities. Holes for instance could be designed into the die casts so that machining cost for brackets is done away with.

As important, aluminum brackets hardware could even be manufactured stronger than steel brackets. Strengthening ribs and radii can be designed into the aluminum die casts resulting in stronger brackets. Pieces need not be joined together as in die casting the aluminum brackets hardware are already produced in net shapes, doing away with welding of parts which could fail with the passage of years. The load factor is also enhanced with aluminum brackets as these are lighter than steel.

This light weight yet sturdy characteristic of aluminum has been put to advantage in the aircraft industry. For instance, the Boeing 747-700 airplanes employ die cast aluminum brackets hardware in their seat back tray tables, providing absolute support to passengers’ in-flight meals or laptop computers of itinerant business executives.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com