Kinetic Die Casting Company makes many types of aluminum hardware, such as aluminum handles. Aluminum Handle Hardware parts are common everywhere. These handles are in vehicles, cars, doors, enclosures, equipment and homes. Hardware parts from aluminum handles or brackets are …

Continue reading

Tag Archives: Aluminum Die Casting

Golf Products made from Aluminum Die Casting

Golf Products made from Aluminum Die Casting. Golf products are just one of the many things that you can produce with aluminum die casting. This process, known popularly as die casting, involves producing parts made out of strong, cost-efficient, and durable alloys and materials. This is done by forcing molten metal into aluminum or steel die cast molds through high pressure. Interestingly enough, the molds being used can be designed in such a way that they can produce complex shapes that make it more durable, tolerable, and long-lasting. Golf handles, balls, and parts used in golf carts are just some of the golfing equipment that can be made with aluminum die casting.

Because aluminum die casting produces the parts fast and are known to be durable, stable, and can be made into different shapes, most manufacturers of golf products use this method to create their aluminum golf products. Addressing the need to produce golf products that actually improve a player’s game, many companies are now selling aluminum golf products in the market today. Golf players prefer aluminum die castings of their golf products not only because of their cheaper prices but also when molded, shaped, and produced properly, these products can improve their game and lessen their handicaps. Some examples of these golf products are golf ball warmers, the heads of golf clubs, aluminum handles, brackets, and knobs in golf pull carts, and so on and so forth.

Die Casting Aluminum Heat Sink Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Heat Sinks. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Why Aluminum Boxes?

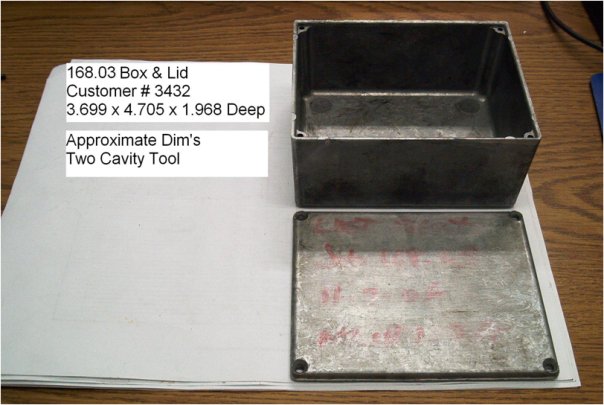

Why Aluminum Boxes? To protect electronic machinery or components from the damages which water, moisture, dust, or abrupt shock can do, one has to use boxes which has the capability to keep the said factors away. This answers the question, “Why should you use Die Casting Aluminum Boxes?” It is because the die casting aluminum boxes can protect components from outside factors since they are made from aluminum die castings and also have die cast lids. The die cast covers can be bolted in place as a way of sealing the item. This will protect the components from factors which causes damages.

Why Aluminum Boxes? To protect electronic machinery or components from the damages which water, moisture, dust, or abrupt shock can do, one has to use boxes which has the capability to keep the said factors away. This answers the question, “Why should you use Die Casting Aluminum Boxes?” It is because the die casting aluminum boxes can protect components from outside factors since they are made from aluminum die castings and also have die cast lids. The die cast covers can be bolted in place as a way of sealing the item. This will protect the components from factors which causes damages.

Die cast aluminum boxes can also be utilized for RF/EMI shielding. This RF (Radio Frequency) or EMI (Electrical Magnetic Inductance) shielding is important if one wants to shield electronic components from unwanted interference which radio waves and frequencies can cause. Through the use of die casting aluminum boxes, electronic components are given RF/EMI shielding since the boxes have the capability of dispersing and absorbing any external frequencies. Utilization as enclosure for computer disk drives, computer components, engine compartments, motors, communication devices, electrical junction boxes, or car transmission is also one of the reasons why these boxes should be used. Since aluminum die cast parts are also less heavy than steel parts, as a manufacturer, it is more beneficial to use this. Aside from being electrically conductive, it will allow easier and less cost of transportation since it only weigh 1/3 of the weight of the steel parts.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

50 Percent Duty on Aluminum Imports

818-982-9200

www.kineticdc.com

As the White House prepares to submit the Trans-Pacific Partnership to Congress in the coming months, it has been touting its record on trade enforcement to persuade lawmakers to vote for the 12-nation pact. The United Steelworkers union on Monday upped the ante on that front by asking President Barack Obama to impose a 50 percent duty on aluminum imports from China and other suppliers as soon as July.

The U.S. International Trade Commission would normally take up to six months to investigate the Section 201 petition for global import relief and make recommendations to Obama, who would have another two months to decide what action to take. However, the union is asking the ITC to make a finding of “critical circumstances” within 60 days so Obama can act quickly to keep additional U.S. aluminum smelters from closing.

If the trade panel makes that determination, the president would then have 30 days to approve some of type of provisional relief while the Section 201 case proceeds for another six to eight months, Terry Stewart, a lawyer for the union group, said.

The timing isn’t ideal for Obama’s TPP push. The aluminum case potentially puts the president on the spot by forcing him to decide whether to impose the 50-percent “provisional” duty sought by the steelworkers while the Section 201 investigation proceeds. If he decides against it or puts in place some lesser relief, that could jeopardize potential votes for the TPP pact.

Pressure Die Casting vs. Sand Casting

Pressure Die Casting vs. Sand Casting. At lower quantities sand casting is cheaper. Product quantities of over 1000 parts over a few years will cost less as a die casting. Aluminum sand cast tooling roughly costs from $500 – $7,500, depending on the size and complexity. Parts from sand casting cost $10 to $30 each. For 1000 parts the total cost is $37,500. 10,000 parts would cost over $300,000. Pressure die casting tooling on the other hand costs from $5,000 – $25,000, again depending on the size and complexity of the die cast parts. The cost for parts is between $2 to $5 each. 1000 parts would cost $30,000. A savings of $7,500. For 10,000 parts the cost would be $50,000, much less than $300,000 for sand casting parts. Die Casting Tooling can create from 100,000 parts to as much as 1,000,000 pressure die casting aluminum lighting parts.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

600 Ton Harvil Die Casting Machine for Sale

Kinetic Die Casting Company needs to make room for a smaller faster die casting machine. We have two larger 600 ton cold chamber aluminum die casting machines. We only need one. We are looking to sell one of our 600 ton machines. This cold chamber machine is in good condition and ready to run parts. Two issues: You will need to add oil and replace a solenoid coil and a pressure switch. Contact Bob if you are interested in buying the machine we have for sale. The price is very good at $8,000 so that it sells quickly. The machine will be available for viewing after 5/17/16. Call Bob Thomas to set up an appointment 818-982-9200.

Here are a few pictures of our machine for sale:

600 Ton Harvil, operator side

www.kineticdiecasting.com

Harvil Die Casting Machine, shot accumulator (intensifier)

www.kineticdiecasting.com/profile.html

www.kineticdiecasting.com/profile.html

Harvil machine, helper side, closing accumulator.

Kinetic Die Casting Company, 6918 Beck Avenue, North Hollywood, CA 91605. 818-982-9200 sales@kineticdc.com

Call us or email us if you are interested in buying our 600 Ton Harvil Die Casting Machine for Sale