Almond Roca for Purchase Orders Special. Our Valentine’s Day Almond Roca Special is open to all our customers. For every purchase order (PO) for parts or die casting tooling we receive the buyer will receive a half pound bag of …

Continue reading

Tag Archives: aluminum parts

Die Casting Molds and Die Casting Procedures

Die Casting Molds and Die Casting Procedures. Die casting aluminum is a process in which many industrial products and accessories are produced. And in producing these industrial products and accessories by way of die cast molds, four major steps are considered crucial and important.

The preparation of the molds that will be used in the process is the first step. The molds in question will be sprayed with lubricant and will be closed. The spraying of the lubricant is necessary so as to effectively control the temperature of the die and also to ensure that the finished product will be removed with ease.

Furthermore, when the diecasting molds have been sprayed, the molten metal will then be introduced to the die and this will be subjected under very high pressure. This kind of pressure will be maintained up until the time that the metal has formed. When the metal has been formed within the mold, the die will then be opened and the shot will be ejected by the ejector pins. From here the scrap that includes the runners, flash and the gate will be taken out from the casting which in turn is done with the use of the special trim die in power press.

Also, there is a traditional way of taking the product out of the casting. This is done by hand or can be done by sawing. This will give some rough edges which can be remedied by grinding so as to smooth out the scrap marks. Another way is to tumble the shots and this can be done if the gates present are thin.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Cast Aluminum Heat sink Purposes

Aluminum is the ideal raw material to be used in making heat sinks because this part should be very durable. Aluminum is known to be a more durable metal compared to other metals including steel. At the same time, it is very abundant and easy to acquire which makes it a cheap material as well. Aluminum Heatsinks are used in electronic products and even appliances. Its purpose is to divert the heat produced by the electrical wires from the other more sensitive parts of the product. In other words, it is used as a safety feature to insure that the electrical device or appliance work perfectly and do not overheat.

Aluminum is the ideal raw material to be used in making heat sinks because this part should be very durable. Aluminum is known to be a more durable metal compared to other metals including steel. At the same time, it is very abundant and easy to acquire which makes it a cheap material as well. Aluminum Heatsinks are used in electronic products and even appliances. Its purpose is to divert the heat produced by the electrical wires from the other more sensitive parts of the product. In other words, it is used as a safety feature to insure that the electrical device or appliance work perfectly and do not overheat.

Furthermore, Aluminum Heatsinks are used in many products all over the world which means that they are needed in large quantities at any given time. To produce them in an efficient and fast manner, the process known as die casting is used.

Die casting Aluminum Heatsinks have three simple steps.The first step is to take the aluminum bar and liquefy it by heating the bar. Once the aluminum is turned to liquid, the next step is to inject it to die cast molds or castings so that it will take on its proper shape. When the casting cools, all that is left is to polish it and a few finishing touches.

Also, Die casting can create consistent results in a fast amount of time. At the same time, it is a relatively cheap process which makes it a very popular method in making not just heat sinks, but other aluminum parts as well.

Die Casting Aluminum Heat Sink Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Heat Sinks. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Parts and the Tooling

Aluminum Parts and the Tooling. Aluminum die casting need a lot of tools and parts to make the perfect dies. The process has been well known to provide an easy method for many constructors to create the most ideal components to different automobiles and the likes. Aluminum parts types are not that easy to characterize especially for a person who is quite new in the die casting process. Since the system also involves a series of molten metals from copper, lead and zinc, a lot of aluminum part types are needed to come up with the best die that possesses the exact instructions by the client. Cold chambered and hot chambered are just two of the aluminum parts types specifically used for the actual machine in die casting.

Aluminum Parts and the Tooling. Aluminum die casting need a lot of tools and parts to make the perfect dies. The process has been well known to provide an easy method for many constructors to create the most ideal components to different automobiles and the likes. Aluminum parts types are not that easy to characterize especially for a person who is quite new in the die casting process. Since the system also involves a series of molten metals from copper, lead and zinc, a lot of aluminum part types are needed to come up with the best die that possesses the exact instructions by the client. Cold chambered and hot chambered are just two of the aluminum parts types specifically used for the actual machine in die casting.

Die casters choose to apply all aluminum part types while die casting. This makes the process more experimental, and can sometimes produce the best outputs at the end of the sessions. However, there is a startling difference between a cold chambered die casting machine from a hot chambered one. For instance, a die caster cannot simply use hot chambered types when dealing with aluminum material. This type of material is more compatible to a die casting machine that is cold chambered. Molds for aluminum die casting may also have parts that do not need cavities. This type of mold greatly differs in price compared to those with cavities.

Furthermore, a lot of the parts sold for aluminum die casting often come with substantial product descriptions to let you determine which of the aluminum part types you are about to purchase like Aluminum Handle Hardware and Aluminum Bracket Hardware.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Different Types of Aluminum Castings

Different Types of Aluminum Castings. Aluminum die castings are used to by a lot of metalworking companies to form the perfect aluminum material, without having to spend a lot of money and wasting a lot of time. Due to the versatility of these processes, a lot of companies have turned to this unique way in forming one of the most dependable alloys that is used for several components in the same industry. There are a lot of items that were produced out of aluminum castings from the Washington Monument’s cap to the ancient tea kettles used by people who lived hundreds and hundreds of years ago. Although there have been a lot of improvements in the process of aluminum castings, most of the companies still resort to the traditional means of using molten metal to form some of the most intricate dies in history.

Different Types of Aluminum Castings. Aluminum die castings are used to by a lot of metalworking companies to form the perfect aluminum material, without having to spend a lot of money and wasting a lot of time. Due to the versatility of these processes, a lot of companies have turned to this unique way in forming one of the most dependable alloys that is used for several components in the same industry. There are a lot of items that were produced out of aluminum castings from the Washington Monument’s cap to the ancient tea kettles used by people who lived hundreds and hundreds of years ago. Although there have been a lot of improvements in the process of aluminum castings, most of the companies still resort to the traditional means of using molten metal to form some of the most intricate dies in history.

Furthermore, Aluminum castings can come in three diverse methods. Out of the three (permanent mold casting, sand casting and die casting), die casting is considered as the most popular among all companies in the metalworking industry. Although sand casting is known to be more versatile due to its delicate patterns, die castings prove to produce the most durable components used by a lot of automobile franchises and even the smallest of modern electronic gadgets. Other would say, however, that permanent mold castings also produce durable materials, but may need more expensive equipments and methodologies compared to the two other methods. Although these three processes may have a lot of differences, it can be agreed that aluminum die castings are highly effective in whichever method they are performed under.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

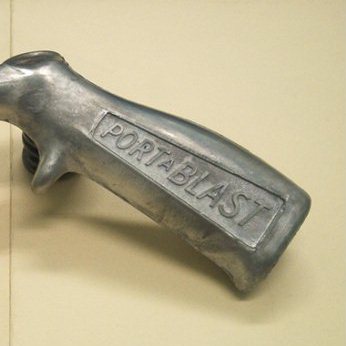

Aluminum Hardware Handles-Die Casted

Die Casted Aluminum Hardware Handles. Hardware handles are made specifically to open doors among other things. This means that these handles are designed to be pushed, pulled and bluntly, take a lot of punishment throughout their existence. Because of that, hardware handles need to be very strong and very durable so that it can last a long time. With that in mind, what better way to make these handles than with aluminum? Aluminum Hardware Handles are essentially stronger and much more durable than any other handle of different material including steel. At the same time, Aluminum Hardware Handles are very light, and of course, cheap.

Die Casted Aluminum Hardware Handles. Hardware handles are made specifically to open doors among other things. This means that these handles are designed to be pushed, pulled and bluntly, take a lot of punishment throughout their existence. Because of that, hardware handles need to be very strong and very durable so that it can last a long time. With that in mind, what better way to make these handles than with aluminum? Aluminum Hardware Handles are essentially stronger and much more durable than any other handle of different material including steel. At the same time, Aluminum Hardware Handles are very light, and of course, cheap.

Furthermore, Aluminum can be mined in the earth and are extracted from ore. Even if people consider this to be a very valuable material because of its unique characteristics, it is cheap because it can be found in abundance. In molding this material into the proper shape, the best method is die casting.

Also, Die casting is the process of turning metal into a finished product. Aluminum is commonly used in this process but zinc and copper can also be used. The first step is to turn the metal alloy into liquid by heating it. When the metal is already liquefied, it will be injected to molds that will shape the metal into Aluminum Hardware Handles.

Die Casting Aluminum Hardware Handles would result in consistent products with high quality. At the same time, it is a fast and efficient process in producing aluminum based parts. When it comes right down to it, companies and manufacturers truly benefits with die casting.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com