Automotive Die Casting Parts from Kinetic Die Casting Company Kinetic Die Casting Company makes several auto parts for our customers. This automotive parts video shows a few of the automotive parts we produce for our customers. On our website, we …

Continue reading

Tag Archives: auto parts

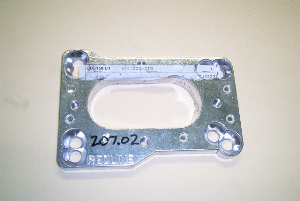

Automotive Parts Made with Zinc Die Castings

Useful Information about Die Casting Zinc Automobile Parts. Manufacturing automobiles normally include die casting zinc automobile parts. An automobile is composed of thousands of parts, countless of which are manufactured from zinc. Zinc may also be joined with other alloys to attain detailed purposes. There are useful reasons why die castings is done for manufacturing cars and other four-wheeled vehicle parts:

• Cars are mass manufactured and need many mechanisms; die casting is a fast yet dependable technique to generate metallic parts for them

• Die casting is multipurpose and has the prospective to make parts in changeable shapes and sizes

• The subsequent goods are sturdy and very long-lasting

• It’s inexpensive to die cast car parts likened to other forms of production

• Die casts are readily recyclable and non-toxic

Zinc is an outstanding choice of alloy for constructing auto parts because it is unbending, hard, small, lightweight, non-sparking, and not corrosive. The bulk of vehicles have zinc parts in them because they perform well and are low-priced to produce. Here are some uses of die casting zinc automobile parts:

• For shielding electronic components

• For enclosing airbags, sensors, telematics, switches, and other sensitive equipment

• For constructing solid items, such as lock barrels, seat belts, etc.

• For ornamental purposes – metal platings, finishes, and designs

Though die casting zinc automobile parts is an acclaimed procedure, the quality shaped still be contingent on what the manufacturer does. When buying auto parts, search for a die caster with a decent track record of creating quality parts that have passed difficult testing.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

Heat Protection for Devices

Heat Protection for Devices. The laws of physics dictate that everything produces heat and work as a product of energy usage. This can be seen in computers and other devices which functions properly and produces heat due to the use of electrical energy. These devices however are prone to heating especially when they are being used constantly for extensive periods of time. One way to prevent overheating is by the use of heat sinks. Heat sinks are auxiliary components that direct the heat away from the device to allow cool air to circulate inside the device. They are made using either copper or aluminum although the latter is more commonly used.

Aluminum heat sinks can be attached to devices in numerous ways depending on their attachment properties. This is also dependent on the device on which the heat sink will be attached to. Usually, heat sinks are placed near major sources of heat to improve their efficiency in cooling the device. Some heat sinks are placed near vents to improve ventilation and circulation of cool air while some heat sinks are placed near important hardware components so that they will maintain their functionality for a longer period of time.

Aluminum heat sinks can be purchased either by visiting a store or by online purchasing. Heat sinks come in many different variants with some heat sinks proving to be more effective than others. When purchasing an aluminum heat sink, it is best to understand the specifications, properties, and the standards of the manufacturer to get a grasp on the effectiveness of the heat sink.

Like

Kinetic Die Casting Company on FaceBook

This is the blog on the Kinetic Die Casting Company web site. Kinetic does Aluminum Auto Parts Manufacturing. Look at this website page for more details: www.kineticdiecasting.com/auto.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

What are aluminum die casting parts?

What are aluminum die casting parts? Aluminum die casting parts are casts which are made entirely from aluminum. Aluminum is the most common type of non-ferrous metal that is used in the industry today and the main reason why is because it is cost effective. It is lightweight and can easily withstand the highest types of operating pressure or temperature. It is also nonmagnetic, has strong corrosion resistance and it is also a great conductor of electricity, making it great for electronic devices. Aluminum aids in fuel efficiency and has many uses when it comes to the transport industry because it has unbeatable weight to strength ratio. Some typical uses of aluminum die casting include the realms of electrical housing, telecommunications, home appliances, lighting, power tools, aircraft parts and automotive manufacturing.

The key benefits of aluminum die include the little to no machining requirements and recyclable qualities. In order to produce the castings, the process of die casting is applied. Die casting is a type of versatile process which is based on producing engineered parts by forcing metals under high pressure in a reusable mold. The molds, or die, can be designed in order to produce various shapes and designs based on repeatability and accuracy. Parts can easily be defined with textured and smooth surfaces through the use of aluminum die. Once the casting is done, the output is designed to have serviceable and attractive finishes. Aluminum die castings are among the highest type of mass produced items in the metalworking industry and it can be found in thousands of companies and industrial products. Die cast parts are integral components for products ranging from toys to automobile parts.

Like

Kinetic Die Casting Company on FaceBook

This is the blog on the Kinetic Die Casting Company web site. The most common metal cast is A380 Aluminum Die Casting Alloy. Look at this website page for more details: www.kineticdiecasting.com/tech.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

Sand Casting Compared to Die Casting

Sand Casting Compared to Die Casting. If you are wondering which is better- sand casting or die casting – then this is the right article for you. Whether you need to know about sand casting or die casting advantages or a assessment of both, this article will certainly help you.

In order to have a stronger view of what is better, you must first know what these two methods are all about. Sand casting, as its name proposes, forms its mold with the help of a pattern or model which is pressed into a kind of sand mixture. Die casting on the other hand utilizes toughened tool steel as a mold in making its cast parts.

Both processes are decent choices of metal casting method. It just determined by what kind of metal parts you plan to cast or produce. For big hollow metal parts like cast aluminum automobile parts, sand casting is characteristically used. For minor and more detailed metal parts, die casting is the more perfect process. The casting weight range for sand casting is essentially unlimited while die casting has a range from 1oz up to 20 pounds.

When it comes to mass producing parts, which involves intricate details and flat surface, die casting is the more ideal method. It is because die casting process has a dimensional tolerance of as low as .001 inch, while sand casting has a minimum of .010 inches.

Money-wise, initial expenses for die casting are pricier than the first costs used for of sand casting. Nevertheless, in the long run, die casting has a lot inexpensive labor cost associated to the labor cost experienced by sand casting.

Like

Kinetic Die Casting Company on FaceBook

This is the blog on the Kinetic Die Casting Company web site. We are an Aluminum Die Casting Company. Look at this website page for more details: www.kineticdiecasting.com/aluminum_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

@kineticdc #kineticdc

Die Casting Tooling and Its Importance

Die Casting Tooling and Its Importance. Die casting tooling, otherwise known as dies, are typically prepared from alloy steel. The dies are finished from at least two sections to allow casting elimination. Due to the efficient approach of die casting in some companies, some dies also come in portable slides, with certain sections that can without difficulty drill holes so as to build the ideal shape as demanded by clients from die casters. In the procedure, die casting tooling allows simple production of holes through the predetermined die half. The molten metal is then dispensed into the hole in order to dry in the cavity and manufacture the precise dimensions contoured in the plating. Dies may also have locking pins, which are utilized in order to stick together two halves and to take away the cast part.

Once the die casting machine is put to a close, the two halves are reserved in close contact by the hydraulic pressure inside the equipment. Once this is done, a die casting tooling is fashioned to use as fundamental components for diverse automobiles and construction needs. Aside from the die casting machine being an vital part of the tooling, a die casting trim is also being employed to put off the surplus aluminum which is located around the produced parts. A die casting trim is a critical part of aluminum die casting tooling, as it help diminish the expense brought about by slow production of materials. When this is utilized, the dies are mounted on a trim press so as to aid in bringing together the two die halves.

Kinetic Die Casting manufactures aluminum military parts, aluminum hardware, and aluminum die castings. Visit our website for a quote: Kinetic Die Casting Company