Aluminum Die Cast Auto Parts include radiators, carburetors, gas tanks, valve covers, mirrors, air filter adapters, exhaust systems, body and closure panels, door and trunk handles, auto lamp parts, engine brackets, wheels, master cylinders, ornaments and logos among others. Aluminum …

Continue reading

Tag Archives: Die Casting Company

How are Aluminum Military Parts Used in 2023?

How Are Aluminum Military Parts Used? Aluminum is an especially useful material for the military as there are countless military vehicles and equipment that are made from aluminum or with aluminum parts. The history of aluminum military parts can be traced back to 1892 when the French used aluminum for torpedo boats. In 1896, the United States Army used aluminum canteens and aluminum picket and tent pins. Sometime during the 1890s, the US Navy acquired several wide aluminum sheets to construct a large assembly (perhaps a ship superstructure). Aluminum also played a crucial role for Germany during the First World War as this was the material that Germany decided to use for their army tanks when iron and steel became scarce. During the Second World War, aluminum military parts were used for walkie-talkies, fuel drums for air transport, bridges and pontoons, searchlights, and aircraft landing mats. Presently, the military uses aluminum for its armor, vehicles, and missiles. Aluminum is the material of choice for military parts because it meets the military’s requirements for materials to be used for vehicles, weapons, and armor. Aluminum has the ability to improve protection, is light and mobile without compromising protection, is easy to weld yet is strong, and has the ability to resist corrosion under extreme weather conditions, and all these are factors that are taken into consideration when military equipment is manufactured.

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Kinetic Die Casting is a Los Angeles die casting company that manufactures aluminum and zinc parts. If you would like more information, please visit our website:Kinetic Die Casting Company

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes:

The Uses of Aluminum Lighting Fixture Parts in 2023

The Uses of Aluminum Lighting Fixtures. Aluminum lighting fixture parts are electrical devices mainly used for creating artificial light and illumination for homes and buildings. They are used either for indoor or outdoor lighting fixtures. Before the invention of aluminum die casting, lighting fixtures are created through welding techniques, making the system expensive and time consuming. Now, the science of aluminum die casting makes the process easier and a whole lot faster.

The Uses of Aluminum Lighting Fixtures. Aluminum lighting fixture parts are electrical devices mainly used for creating artificial light and illumination for homes and buildings. They are used either for indoor or outdoor lighting fixtures. Before the invention of aluminum die casting, lighting fixtures are created through welding techniques, making the system expensive and time consuming. Now, the science of aluminum die casting makes the process easier and a whole lot faster.

Usually, Aluminum lighting fixture parts consist of: a light source (lamp), a light reflector, an aperture (with or without lens), an outer shell or housing for alignment and protection, an electric ballast and connection to a power source. They are often used at the automotive lighting industry, marine lighting, medical lighting and aerospace lighting.

Furthermore, Aluminum lighting fixture parts are lightweight, durable and long lasting, making them ideal for several uses. They are often used to strengthen construction both on the inside and outside many establishments. They allow easier construction for different lighting techniques. This makes them very versatile, and can be used for many purposes: medical offices, parking garage lighting, bullet lights, street traffic lights, walk lights, outdoor coach light fixtures and high temperature light fixtures. They are also available in a wide array of shapes and sizes, ensuring better output and production of different lighting systems.

Light Fixture Die Casting Parts

Kinetic Die Casting Company makes aluminum die castings as Lighting Fixture Die Castings. We make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes:

Low Volume Die Casting Supplier 2023

Kinetic Die Casting Company makes thousands of die casting parts every day. Some customers need 100,000 die casting parts a year. Others, fewer. KDC has a few types of customers that purchase lower quantity production die casting parts, less production parts or fewer die cast parts than the typical manufacturing company. Some customers order fewer than 100 die casting parts in a year. Once the die casting tooling is made, the cost to make a few castings is much less than when a manufacturer is getting started.

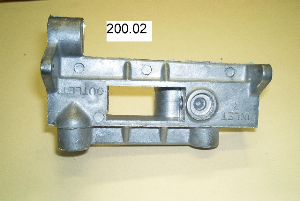

This manufacturing company customer buys 75 of these die casting parts on a purchase order.

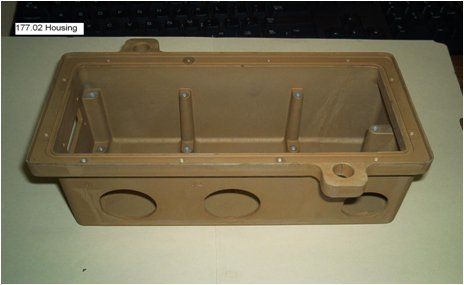

We have a purchase order to make 200 of these parts and ship them in quantities of 7 parts up to 20 parts at a time.

https://www.kineticdiecasting.com/

Kinetic Die Casting Company is a Lower Volume and Lower Quantity Die Casting Supplier.

6918 Beck Avenue

North Hollywood,

California USA 91605

Phone Number:

818-982-9200

800-524-8083

sales@kineticdc.com

Office Hours: Monday – Thursday

8:30 AM – 4:30 PM (Pacific Standard Time)

How are Aluminum Speaker Parts Made in 2023?

How are Aluminum Speaker Parts made? Making aluminum speakers needs the proper tools and materials to be used. But this article will only give you the brief idea on the basic steps in making aluminum speaker parts. So how are Aluminum Speaker Parts made?

Contact Kinetic Die Casting Company to get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Kinetic Die Casting manufactures aluminum military parts, aluminum hardware, and aluminum die castings. Visit our website for a quote: Kinetic Die Casting Company

b>“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes:

Why Use Die Casting in 2023?

Sadly, die-casting is unknown to most of the people around the world. They are not even interested about how their lighting fixtures, appliances and car parts were created. But for the few of you who took their time to search for this page, kudos to you.

Experts in the industry know for a fact that die casting is a very neat and useful technology that is used on creating metal parts and products. Fundamentally, it is not only used in the metal production industry, it is the same technique used in creating plastic products and materials. The only differences are the materials used in the production, and the materials used in the mold.

To refresh your memory (and for those who do not know), here are the following advantages on using die-casting.

- Fast production rates of products.

- Large part quantities produced quickly.

- Fewer added machine operations (compared to other manufacturing methods).

- Lesser manual labor from any personnel involved.

- Inserts, such as high strength bearing surfaces, heating elements, and threaded inserts, can be cast-in.

If you compare it to sand casting and permanent molds, production with it is faster with lesser labor costs. Compared to permanent and sand mold castings, thinner walls can be produced by manufacturing with die casting. Completed products have very smooth cast surfaces. The products die casted have great dimensional accuracy and constancy. If you compare it with forging, it can produce products that are more complex. Alternatively, if you compare it to stamping, section thickness is not an issue with this casting method. If you compare this method and plastic casting, die casting can produce can create stronger high quality products.

As you can see, die casting is definitely a good choice if a person wants to use a metal part in his product. Die casting is the best choice for high quality manufactured metal products. Kinetic Die Casting Company is your best choice for purchasing your die casting products. Call us at 818-982-9200 or email at sales@kineticdc.com

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes: