Reasons for Buying Die Casting Parts from Kinetic Die Casting Company. The reasons for buying aluminum parts and zinc parts from Kinetic Die Casting Company are many. We have many happy customers that talk about our service and quality. Here …

Continue reading

Tag Archives: Die Casting Parts

Die casting and its effect on the world

Die casting and its effect on the world. In recent years, metal has started being used every day. From PCs to TVs and refrigerators, almost every invention created by scientific research is made out of metal.

With its pliability and conductivity properties, it was not a challenging task for early humans to learn a way to use it: through fire. Ultimately, the technology of metal casting (pouring molten metal into a mold) became the normal for “sculpting” implements out of this element. One of the mutual processes diverging out from this is die casting, or the use of a mold cavity to guide molten metal into shape.

The most stress-free method of doing this is zinc die casting. Parts of zinc appliances and even accessories can be finished using zinc die casting. It is the most common procedure because zinc is not tough to handle. Moreover, it produces sturdy materials which are conducive to power and high temperature. Zinc is also high in ductility, which makes it a great material for various products.

In the process of zinc die casting, parts usually include either a hot-chamber die cast or a cold-chamber die cast (reliant on the requirement of the producer) and zinc (or an alloy). The metal is heated to its boiling point. The subsequent liquid is then dispensed into the mold and will take the shape of said mold.

Really, the processing of metal into a pliable creation is an astounding invention – it would accurately shape the future of the world. Zinc die casting, amid others, has aided making the world an easier place to live in.

Do you need fast delivery for die casting parts? Kineticdc shipped parts that were die castings with impregnation, chemical filmed and machined in less than two weeks from receipt of a purchase order. Know someone that wants to buy die cast parts and can use our die casting services?

Call us and let us know 818-982-9200.

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605

www.kineticdc.com #diecasting #kineticdc #manufacturing @kineticdc

Kineticdc makes:

Automotive Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

January 2015 Discount from Kinetic Die Casting Company

Kinetic Die Casting Company is offering a special discount offer found using our Facebook page (www.facebook.com/kineticdc). The offer is very simple. Click “LIKE” to like our Facebook page and send us a purchase order before January 30, 2015 for parts delivery prior to March 30, 2015 and we will discount your part price by 10%, from the prior purchase order part price, for an equal quantity.

Fax your purchase order before 1/30/2015 to 818-982-0877.

There is a purchase order limit of $5,000.

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605

Kineticdc makes:

Aircraft Die Castings

Aluminum Heat Sink Die Castings

Automotive Die Casting Parts

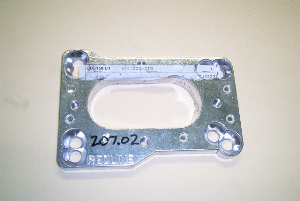

Die Casting Bracket Parts

Light Fixture Die Casting Parts

Enclosure Box Die Castings

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Die Casting Golf Parts

www.kineticdc.com

#discount #diecasting #kineticdc #manufacturing @kineticdc

Zinc Die Casting and Its Potential for Use in Flight

Zinc Die Casting and Its Potential for Use in Flight. Airplanes are an activity enjoyed by many the world over the world enjoys challenging gravity and sending humans (and non-humans) to the sky by sending them on airplanes, space ships, and hot air balloons.

Although it is exhilarating, defying gravity is hard. In order to take flight, aircrafts ready for take-off must be tailored akin to that of a bird’s structure. A bird’s wings are constructed of hollow bones. In the realm of humans, this equates to the use of light but robust material to build the frame of the airplane, airship, or space craft. One procedure of ensuring high quality materials is zinc die casting. Aerospace parts need comparatively lightweight and sturdy materials which can endure strong pressure and impact.

As a non-ferrous metal, Zinc alloy can be liquefied and shaped to a material that can be characterized as such. It is also a low-cost raw material. Owing to the classy nature of the aeronautics industry, the use of zinc as a chief component in the production of objects intended for flight might be a perfect concept.

Moreover, materials made of zinc are decent conductors of electricity and heat. Since flight exposes objects to high stress and pressure, materials made of inferior elements may flop easily. But it has been established that zinc is impervious to fatigue. If combined with another element to produce an alloy, the end product is proved to be sturdier than aluminum and magnesium.

With zinc die casting, zinc aerospace parts are certain to be cheap but without surrendering the features vital of their function.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

Automotive Parts Made with Zinc Die Castings

Useful Information about Die Casting Zinc Automobile Parts. Manufacturing automobiles normally include die casting zinc automobile parts. An automobile is composed of thousands of parts, countless of which are manufactured from zinc. Zinc may also be joined with other alloys to attain detailed purposes. There are useful reasons why die castings is done for manufacturing cars and other four-wheeled vehicle parts:

• Cars are mass manufactured and need many mechanisms; die casting is a fast yet dependable technique to generate metallic parts for them

• Die casting is multipurpose and has the prospective to make parts in changeable shapes and sizes

• The subsequent goods are sturdy and very long-lasting

• It’s inexpensive to die cast car parts likened to other forms of production

• Die casts are readily recyclable and non-toxic

Zinc is an outstanding choice of alloy for constructing auto parts because it is unbending, hard, small, lightweight, non-sparking, and not corrosive. The bulk of vehicles have zinc parts in them because they perform well and are low-priced to produce. Here are some uses of die casting zinc automobile parts:

• For shielding electronic components

• For enclosing airbags, sensors, telematics, switches, and other sensitive equipment

• For constructing solid items, such as lock barrels, seat belts, etc.

• For ornamental purposes – metal platings, finishes, and designs

Though die casting zinc automobile parts is an acclaimed procedure, the quality shaped still be contingent on what the manufacturer does. When buying auto parts, search for a die caster with a decent track record of creating quality parts that have passed difficult testing.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html