Kinetic Die Casting Company Makes Aluminum Auto Parts – A few months ago, an automotive parts customer contacted me; he makes aluminum hydraulic pumps for cars. He asked if he could move his die casting tooling inserts from his current …

Continue reading

Tag Archives: Die Casting Process

Recycling Aluminum Die Castings

Die casting Parts are completely recyclable. Die Casting Parts have a Planet-Saving Value. These days, many manufacturers are turning to aluminum.

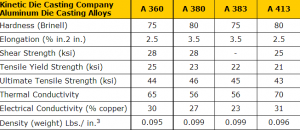

aluminum die casting alloys

Aluminum is a better material to provide their businesses with excellent products that can boost sales. Die casting aluminum is more than just an aluminum production means; it is considered both as an art and a craft.

Unlike plastic, aluminum alloys are completely recyclable. Aluminum is strong and does not deteriorate over time.

Permalink: https://www.kineticdiecasting.com/kdc/recycling-aluminum-die-castings/

The aluminum die casting alloys used in the aluminum die casting process offer designers that are concerned with post-consumer recyclable a highly favorable material option by way of the die cast parts’ reuse feature. Die cast aluminum parts these days, as well as the entire die casting process itself, give product engineers the chance to create and develop aluminum designs that can save the environment. Thus, components in the die casting process are now made to maintain their integrity and quality through disassembly and the consequent tasks of repair, manufacturing, and reassembly – major options that were not available or possible in past years.

What does all this mean? It means that once the lives of die casting aluminum parts end, they are armed with the potential to return to usefulness by becoming part of some other industrial application, and an Kinetic Die Casting Company an aluminum die casting company can indeed help save the planet.

Kinetic Die Casting manufactures products like aluminum hardware, and aluminum boxes. If you would like more information on Kinetic Die Casting, please visit our website:Kinetic Die Casting Company

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Low Quantity Diecastings

Low Production Die Castings Cost. Heating plates are mostly seen in the home and in laboratory equipment that need continuous heating or source of heat like chocolate fountains. Many manufacturers prefer producing heating plates using aluminum alloy because this alloy has thermal properties that are suitable to play the role of heating plates. Many manufacturers also use die casting in producing heating plates because they find it more convenient and economical to use as compared to other processes.

In die casting, aluminum is melted by exposing to extremely high temperature. When the metal is already melted, it will be injected in molds or dies to take the shape of the parts. Afterward, when the metal is already solidified, the parts or casts in the dies will be removed and will be slightly polished. The parts are near net shape, meaning they are produced as whole parts so joints will be avoided. This makes the pressure die casting more efficient because it produces stronger and more durable products unlike other processes like extrusion. In extrusion, the products produced are in cross section making the parts less durable as compared to die casting. Aside from this, heating plates do not need hollow parts like that of what will be produced in extrusion. Lastly, pressure die casting is much inexpensive than extrusion that is why many manufacturers use die casting instead of extrusion.

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Permalink: https://www.kineticdiecasting.com/kdc/low-quantity-diecastings/

Kinetic Die Casting manufactures zinc and aluminium die casting. If you would like a quote, please visit our website:

Die Casting price quote

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Porosity in the Die Casting Process

The steel die cavity is sprayed with a liquid release agent to prevent the molten metal from sticking to the steel cavity. Much like the cook will spray a pan before baking a cake. The spray dissipates into steam because the die is very hot. Porosity is natural in the Die Casting Process. The molten metal is squirted at a very fast speed and under extreme pressure into the die. It is like a running water hose with a thumb on the nozzle. The metal is moving very rapidly as it is forcibly injected into a steel die cavity, the metal picks up voids and air bubbles from the steam and the turbulence of the injection. The metal is squeezed into the die with a piston to evacuate or to remove and compress most of the voids and air pockets. Those voids and air pockets are called die casting porosity. It is a natural occurrence in the production of die casting parts. To read more about die casting porosity, review our web page: http://www.kineticdiecasting.com/porosity.html

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Permalink: https://www.kineticdiecasting.com/kdc/porosity-in-the-die-casting-process-2/

Kinetic Die Casting Company

E-mail sales@kineticdc.com / 818-982-9200 / 800-524-8083 Toll Free / 818-982-0877 Fax

6918 Beck Avenue, North Hollywood, California USA 91605,

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

High Pressure Die Castings

What is the High Pressure Aluminum Die Casting Process?

The image pictured above depicts a Cold Chamber Die Casting Machine as it makes parts. The term “Cold Chamber Die Casting” refers to a separate metal melting furnace. The High Pressure Die Casting, cold chamber die casting process follows this sequence:

1. Look at the image above

2. The die casting machine opens the die casting mold.

3. The prior part is removed and the die cast mold is sprayed for the next part

4. The aluminum is poured using a ladle into a shot cylinder

5. The shot piston injects the metal into the die casting mold.

6. The machine opens and the process starts again.

For more details, look at this webpage: http://www.kineticdiecasting.com/what-is-die-casting.html

Kinetic Die Casting Company

6918 Beck Avenue, North Hollywood, CA 91605

Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

sales@kineticdc.com

Permalink: https://www.kineticdiecasting.com/kdc/high-pressure-die-castings/

Sand Castings in 2017

What is Sand Casting? Sand casting is a metal part manufacturing process that uses sand as the form or mold that shapes the metal castings. In sand casting, the sand is moistened and the pattern is pressed into the sand. The preparation and bonding process of the sand is the most critical step in the process. This technique is usually used for low volume production.

The sand casting pattern is made of wood or metal, such as aluminum. The patterns are generally not destroyed but are made permanent to be reused up to a few thousand times. Sand casting is used when lower quantities are needed and lower quality is acceptable. Manufacturing companies use sand casting to make aluminum parts if the project only needs a few hundred parts.

Permalink: https://www.kineticdiecasting.com/kdc/sand-castings-in-2017/

Kinetic Die Casting Company sales@kineticdc.com

6918 Beck Avenue North Hollywood, California, 91605, USA

800-524-8083 or 818-982-9200 or fax 818-982-0877