Remember to vote today. Vote today because every election matters. Vote today because the choices you will make matter. Vote today because elections aren’t simply about your representatives in Washington or who is president. Who you choose this November to …

Continue reading

Tag Archives: die casting

Plastic Injection Molded Parts 2019

Aluminum Die Casting Parts vs Plastic Injection Molded Parts.

Plastic Injection molding and aluminum die casting are similar in a lot of ways:

Plastic Injection molding and aluminum die casting are similar in a lot of ways:

- Both require a mold or tool to produce parts.

- The tooling cost is very similar in both industries.

- Both processes inject material into a mold to make parts.

- Both processes can make hundreds or thousands of parts every day.

Plastic Injection Molded Parts

Advantages

- Plastic parts are produced at a lower temperature than aluminum parts, plastic melts at only a few hundred degrees Fahrenheit

- Plastic Parts weigh less than aluminum die casting parts.

Disadvantages:

- Plastic is not typically biodegradable

- Plastic parts require metal inserts to hold a thread for screws.

- Plastic does not block EMI/RF waves

- Plastic Parts are not as strong.

Aluminum Die Casting Parts

Disadvantages

- Aluminum parts weigh more than plastic.

- Aluminum parts are produced in only one color and need paint or powder coat for color.

Advantages

- Aluminum naturally shields EMI/RF waves.

- Holes can be directly threaded into the parts.

- Features can be machined into aluminum.

- Aluminum has great thermal transference properties.

- Aluminum is a natural conductor of electricity.

- Aluminum material is environmentally friendly and can be recycled easily when done.

- All aluminum alloys (360, 380, 383, and 413) are made from recycled materials.

- Aluminum parts are stronger than plastic

Plastic Injection Parts vs. Aluminum Die Casting Parts

Kinetic Die Casting is a die casting company specializing in aluminum and zinc parts. If you would like to request a quote, please visit our website:Kinetic Die Casting Company

Steel Parts or Plastic Parts or Die Casting Parts

Metal or Plastic Parts

Custom Metal Part Castings

Die Casting Parts Porosity

Die Casting Pats Photos

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Part Prices

Aluminum Enclosures 2019

What sensation aluminum has become in the hardware market is no secret. The metal and its derivatives are being widely being used in not only huge companies such as automobiles and aeronautics but also in small scale usage such as boxes and enclosures for mundane activities. Here is guide to the benefiting properties which make aluminum a favorite over its other metal and alloy counterparts, especially when it comes to boxes and enclosures. This article would also successfully hope to throw light on different purpose for which the boxes are being manufactured for.

DURABILITY

As of now, Aluminum is the most durable and its product the most stable, as compared to any other metal and its products if gauged on the scale of practical use. The aluminum boxes and enclosure, whether big or small are highly resistant to corrosive reactions and this one property is largely responsible for aluminum’s long life span.

PROTECTS THE STORED MATERIAL

Also, Aluminum alloy and the derivatives obtained from it have a very low reactivity when they come in contact with air. There may be many elements and metals which are much lighter and durable than aluminum but lose out because they react vigorously when kept in the atmosphere. These highly reactive metals cannot be used to make something for casual use like normal boxes. Aluminum, being low on reactivity protects the stored material inside form reactants and attacks from outside.

LIGHTER AND GOOD TEXTURE

Furthermore, Aluminum is very light as compared to other alloys/metals. This is one reason that huge enclosures which to be transported over long distances are made out of aluminum so that loading and unloading is a much easier task.

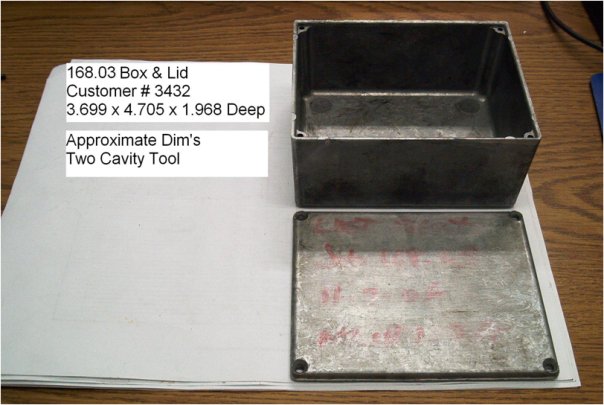

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Casting Boxes and Enclosure Die Castings

Die Casting Box Parts

Kinetic Die Casting Newsletter Articles

Die Casting Parts Draft Angle

Die Casting Box Pictures

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Box Prices

Aluminum Heat Sinks 2019

Aluminum Heat Sinks Keeps Things Cool. A lot number of products currently in the market and currently in production today make use of parts known as Aluminum Heatsinks. These heat sinks are used in many appliances and electronic devices today and their main purpose is to remove or divert the heat generated by the electric current going through the wires or by other components of the product. This is placed so that the more important components of the machine will not be affected by the heat and would function normally.

Aluminum is used for this because of its characteristics. First and foremost, it is one of the most strong and durable materials. It is a fact that aluminum is just as strong if not stronger than steel. Secondly, it is one third of the weight of steel, this is important so that the Aluminum Heat sinks will not add too much weight on the product. It is also flexible, easy to use and very cheap as it can be mined almost anywhere. Lastly, aluminum can be used in die casting.

Furthermore, a popular method of mass producing parts and other products is known as die casting. This method of manufacturing starts with liquefying the aluminum by exposing it in intense heat. The resulting liquefied material is then placed into die cast molds. These molds will give the aluminum its new shape once it has cooled down and hardened back to its solid state. After doing some finishing touches and fine tuning of the product, the results are identical, high quality Aluminum Heatsinks.

Aluminum Heat Sinks 2019

Die Casting Aluminum Heat Sink Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Heat Sinks. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Heat Sink Die Castings

Chocolate Fountain Die Castings

Die Casting Heat Sinks

Die Casting Heat Sink Pictures

Golf Products Die Castings

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Die Casting Heat Sink Prices

Job Die Casting Machine Operator 2019

Kinetic Die Casting Company Machine Operator Job. Full time 40 hours per week $12 – $18 per hour. A die casting machine operator must be able to efficiently operate a die casting machine to make good quality die casting parts. The die casting machine operator should be able to make adjustments to the die casting machine to improve the quality and efficiency of the die casting parts produced in their machine.

Die Casting Machine Operator Job Skills and Job Abilities

* Have experience operating an aluminum die casting machine.

* Willing to learn to set dies in die casting machine.

* Willing to learn to set trim dies in trim press.

* Must be willing to work as a team member.

* Must be willing to work any shift.

* Must be willing to work overtime.

* Must have reliable transportation to Kinetic Die Casting Company.

* Die casting mold setup experience is a plus.

* Forklift experience is a plus.

* Automatic equipment setup experience for bonus.

How to get a die casting job:

https://www.kineticdiecasting.com/employment.html#How_to_get_the_die_casting_job

Salary and Benefits

* This is a position with growth opportunity.

* Compensation $12 – $18 per hour, based on experience and skills.

Online Job Application: https://www.kineticdiecasting.com/application.php

Kinetic Die Casting Company has Die Casting machine Operator Jobs available.

Kinetic Die Casting Company

https://www.kineticdiecasting.com/

6918 Beck Avenue

North Hollywood Ca. 91605

OR

* Fax: 818-982-0877 or

* Email: sales@kineticdc.com

Call 818-982-9200 for INTERVIEW

500 Automotive Parts Daily

Kinetic Die Casting Company makes 500 Automotive Parts in less than a day. Today, we received a purchase order from one our customers to produce over 1,000 aftermarket auto parts. We will die cast these car parts using aluminum, in less than two days. Send us a purchase order to see how well we serve you. Die Casting of Aluminum Auto Parts is fast and inexpensive. Kinetic Die Casting Company makes thousands of automobile parts every week. We produce several 100 thousand car parts each year using our aluminum die casting production process.

Kinetic Die Casting makes aluminum parts. To get a quote, use this webpage: Die Casting Parts Prices

Permalink: https://www.kineticdiecasting.com/kdc/500-automotive-parts-daily/

Send your purchase order today. Contact us for more information:

Kinetic Die Casting Company (www.kineticdiecasting.com)

6918 Beck Avenue, North Hollywood California 91605 USA

818-982-9200 – sales@kineticdc.com

Kineticdc makes:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

To get a quote, use this webpage: Die Casting Parts Prices