When our customers buy die casting tooling, they have an option to buy single or multiple cavity tools. In die casting, we are limited in the number of parts we make in a die casting shot. “Shot” refers to a …

Continue reading

Tag Archives: die casting

How are Bracket Hardware Made?

How are Bracket Hardware Made? Aluminum Brackets Hardware is used in the process of building houses and other structures. Mainly, these brackets are used to keep things in place during the construction phase when some parts or beams should not move. This part is also used in making chocolate fountains and lighting fixtures to hold the other parts together during the construction process so that it ends up perfectly in place. There are many uses for the Aluminum Die Casting Brackets Hardware which is why it needs to be produced fast and cheap and not only that, it is required to be very strong. This is why aluminum is used in making this bracket because aluminum isn’t only abundant, it is considered to be stronger than steel and lighter as well.

How are Bracket Hardware Made? Aluminum Brackets Hardware is used in the process of building houses and other structures. Mainly, these brackets are used to keep things in place during the construction phase when some parts or beams should not move. This part is also used in making chocolate fountains and lighting fixtures to hold the other parts together during the construction process so that it ends up perfectly in place. There are many uses for the Aluminum Die Casting Brackets Hardware which is why it needs to be produced fast and cheap and not only that, it is required to be very strong. This is why aluminum is used in making this bracket because aluminum isn’t only abundant, it is considered to be stronger than steel and lighter as well.

Since Aluminum Brackets Hardware is made through a process known as die casting, it becomes even stronger than steel brackets. The latter is made in pieces and assembled by welding them together. In die casting, there is no need to weld the pieces. This process starts with melting the aluminum bar into liquid. Once the metal is liquefied, it can be placed in large die cast molds so that it will take on a new shape, in this case the shape of a bracket. When it cools down overtime, the result is a single piece of bracket and not several pieces that need to be weld together as welding points can create weak spots.

Furthermore, Aluminum Brackets Hardware is an integral part of construction and the manufacturer needs to be able to trust this part. With the die casting process, the manufacturer will be able to rely on it a hundred percent.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Cast Aluminum Heat sink Purposes

Aluminum is the ideal raw material to be used in making heat sinks because this part should be very durable. Aluminum is known to be a more durable metal compared to other metals including steel. At the same time, it is very abundant and easy to acquire which makes it a cheap material as well. Aluminum Heatsinks are used in electronic products and even appliances. Its purpose is to divert the heat produced by the electrical wires from the other more sensitive parts of the product. In other words, it is used as a safety feature to insure that the electrical device or appliance work perfectly and do not overheat.

Aluminum is the ideal raw material to be used in making heat sinks because this part should be very durable. Aluminum is known to be a more durable metal compared to other metals including steel. At the same time, it is very abundant and easy to acquire which makes it a cheap material as well. Aluminum Heatsinks are used in electronic products and even appliances. Its purpose is to divert the heat produced by the electrical wires from the other more sensitive parts of the product. In other words, it is used as a safety feature to insure that the electrical device or appliance work perfectly and do not overheat.

Furthermore, Aluminum Heatsinks are used in many products all over the world which means that they are needed in large quantities at any given time. To produce them in an efficient and fast manner, the process known as die casting is used.

Die casting Aluminum Heatsinks have three simple steps.The first step is to take the aluminum bar and liquefy it by heating the bar. Once the aluminum is turned to liquid, the next step is to inject it to die cast molds or castings so that it will take on its proper shape. When the casting cools, all that is left is to polish it and a few finishing touches.

Also, Die casting can create consistent results in a fast amount of time. At the same time, it is a relatively cheap process which makes it a very popular method in making not just heat sinks, but other aluminum parts as well.

Die Casting Aluminum Heat Sink Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Heat Sinks. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

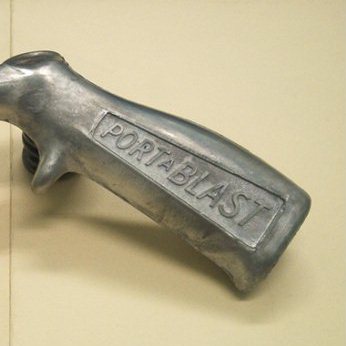

Aluminum Hardware Handles-Die Casted

Die Casted Aluminum Hardware Handles. Hardware handles are made specifically to open doors among other things. This means that these handles are designed to be pushed, pulled and bluntly, take a lot of punishment throughout their existence. Because of that, hardware handles need to be very strong and very durable so that it can last a long time. With that in mind, what better way to make these handles than with aluminum? Aluminum Hardware Handles are essentially stronger and much more durable than any other handle of different material including steel. At the same time, Aluminum Hardware Handles are very light, and of course, cheap.

Die Casted Aluminum Hardware Handles. Hardware handles are made specifically to open doors among other things. This means that these handles are designed to be pushed, pulled and bluntly, take a lot of punishment throughout their existence. Because of that, hardware handles need to be very strong and very durable so that it can last a long time. With that in mind, what better way to make these handles than with aluminum? Aluminum Hardware Handles are essentially stronger and much more durable than any other handle of different material including steel. At the same time, Aluminum Hardware Handles are very light, and of course, cheap.

Furthermore, Aluminum can be mined in the earth and are extracted from ore. Even if people consider this to be a very valuable material because of its unique characteristics, it is cheap because it can be found in abundance. In molding this material into the proper shape, the best method is die casting.

Also, Die casting is the process of turning metal into a finished product. Aluminum is commonly used in this process but zinc and copper can also be used. The first step is to turn the metal alloy into liquid by heating it. When the metal is already liquefied, it will be injected to molds that will shape the metal into Aluminum Hardware Handles.

Die Casting Aluminum Hardware Handles would result in consistent products with high quality. At the same time, it is a fast and efficient process in producing aluminum based parts. When it comes right down to it, companies and manufacturers truly benefits with die casting.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Casting Advantages for Auto Parts

Die Casting Advantages for die casting parts used for Auto Parts. Strength and reliability – These are the most important requirements for automobile parts. Today, the automobile industry has a strong demand for die castings used for car parts. Die casting is a metal working process that performs efficiently on large-scale production. If we will compare it with other processes like sand casting, forging and extrusion, die casting produces car parts with higher yield strength (breaking point). It is used to produce both mechanical and fixed parts of automobiles.

The tools for automobile die castings are expensive, reaching many thousands of dollars. The capital expenditure makes the process suitable only for large-scale manufacturing companies. However, it is a good investment because it minimizes human intervention for die castings used for car parts. Die casting products are precise in depth, size and shape. This is perfect for motor housings, enclosures, pumps and hardware for cars. The process produces little or no scrap and deformities. Therefore, there is little need for post machining. If there is any scrap, they can easily be recycled.

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Worldwide Used Consumer Die Castings

Worldwide Used Consumer Die Casting. For the business of manufacturing bulk orders of parts made from non ferrous metals such as tin, zinc, copper or the most popular of them all, aluminum. Aluminum has become very popular in Consumer Parts Die Castings because of its unique properties. It is one of the most sought after metal alloys in the world and at the same time, it is very easy to find. It can be mined of the top of the earth by grinding ores. They are known to be as hard, as tough and as strong as steel, however aluminum is just a third of the weight of steel of the same size, making it an even better choice for some manufacturers of Consumer Parts Die Castings. But, how exactly is die casting accomplished?

Worldwide Used Consumer Die Casting. For the business of manufacturing bulk orders of parts made from non ferrous metals such as tin, zinc, copper or the most popular of them all, aluminum. Aluminum has become very popular in Consumer Parts Die Castings because of its unique properties. It is one of the most sought after metal alloys in the world and at the same time, it is very easy to find. It can be mined of the top of the earth by grinding ores. They are known to be as hard, as tough and as strong as steel, however aluminum is just a third of the weight of steel of the same size, making it an even better choice for some manufacturers of Consumer Parts Die Castings. But, how exactly is die casting accomplished?

Also, die casting is similar in many ways to another manufacturing business process known as permanent mold casting, wherein the material that is to be used to create the parts are first liquefied by exposing it in extreme temperatures. When the material becomes liquid, it will be poured into molds. In permanent die cast mold casting, after the liquid material has been poured into the molds it will be allowed to cool and harden, in die casting the molds are subjected to high amounts of pressure first to ensure that the material gets into every nook and cranny of the mold. In this way, Consumer Parts Die Castings give better and more accurate results compared to any other manufacturing process to create small or medium sized parts.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com