Battling China on Price Businesses say Chinese-made items are pricier than Mexican if you consider costs associated with quality, logistics, and engineering changes Like many U.S. purchasing managers, Fred Heegan found himself under pressure over the “China price.” Heegan is …

Continue reading

Tag Archives: die casting

Support from Aluminum Brackets Hardware

Get absolute support from aluminum brackets hardware. Structural integrity is a foremost consideration among architects and engineers in constructing homes and buildings. Aluminum brackets hardware has therefore become a major component in the construction of houses, buildings and other structures. Through the metallurgical process of die casting, the advantages of constructing with aluminum materials have been brought to the fore, leading to the development of various types of brackets such as the multi-purpose servo bracket and angle bracket.

Get absolute support from aluminum brackets hardware. Structural integrity is a foremost consideration among architects and engineers in constructing homes and buildings. Aluminum brackets hardware has therefore become a major component in the construction of houses, buildings and other structures. Through the metallurgical process of die casting, the advantages of constructing with aluminum materials have been brought to the fore, leading to the development of various types of brackets such as the multi-purpose servo bracket and angle bracket.

Construction cost can be considerably reduced using aluminum brackets hardware which is cheaper to mass-produce through die-casting. This process involves pouring molten aluminum into molds that could be designed into specifically designed shapes or cavities. Holes for instance could be designed into the die casts so that machining cost for brackets is done away with.

As important, aluminum brackets hardware could even be manufactured stronger than steel brackets. Strengthening ribs and radii can be designed into the aluminum die casts resulting in stronger brackets. Pieces need not be joined together as in die casting the aluminum brackets hardware are already produced in net shapes, doing away with welding of parts which could fail with the passage of years. The load factor is also enhanced with aluminum brackets as these are lighter than steel.

This light weight yet sturdy characteristic of aluminum has been put to advantage in the aircraft industry. For instance, the Boeing 747-700 airplanes employ die cast aluminum brackets hardware in their seat back tray tables, providing absolute support to passengers’ in-flight meals or laptop computers of itinerant business executives.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Lighting Fixtures–Die Casted

Aluminum Lighting Fixtures–Die Casted. The die casting manufacturing process is quite similar to permanent mold casting. Both processes start out by melting or liquefying the material such as resin, rubber, zinc, copper and aluminum to name a few, that is going to be used. The melted materials will then be injected into die cast molds castings. The liquid will then take the form of the patterns in the mold castings. The molds will then be allowed to cool down to harden and once they are opened, the product is finished. The difference between die casting and permanent mold casting is that the former uses high amounts of pressure in the molds so that the material will get into every part of the pattern. This results in better quality of the products which is why die casting is chosen to make Aluminum Lighting Fixtures.

Aluminum Lighting Fixtures–Die Casted. The die casting manufacturing process is quite similar to permanent mold casting. Both processes start out by melting or liquefying the material such as resin, rubber, zinc, copper and aluminum to name a few, that is going to be used. The melted materials will then be injected into die cast molds castings. The liquid will then take the form of the patterns in the mold castings. The molds will then be allowed to cool down to harden and once they are opened, the product is finished. The difference between die casting and permanent mold casting is that the former uses high amounts of pressure in the molds so that the material will get into every part of the pattern. This results in better quality of the products which is why die casting is chosen to make Aluminum Lighting Fixtures.

Also, Aluminum Lighting Fixtures help in illuminating man made structures such as houses, buildings, tunnels as well as the streets at night. They are an essential part of these structures and a lot of them are needed. By using the die casting process, the bulk orders for these Aluminum Lighting Fixtures are met. Not only that, quality and consistency is insured by die casting. This is a cost efficient and effective way of producing Aluminum Lighting Fixtures.

Furthermore, Aluminum is a great choice for lighting fixtures as they are strong and can last a very long time. They are also very lightweight compared to other metals. Since they can be harvested almost anywhere, they are very cheap too.

Light Fixture Die Casting Parts

Kinetic Die Casting Company makes aluminum die castings as Lighting Fixture Die Castings. We make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

The Roles in Welding Aluminum Parts

The Roles in Welding Aluminum Parts. Have you ever heard of welding? The welding industry is growing fast and the requirements for the materials are also getting tough. It is in this sense that the welding companies see the usefulness of aluminum and its alloys. Basically, the aluminum die cast parts types are fairly amenable when it comes to welding metalwork pieces. Aluminum is after all considered to be one of the best metals to use because of its fluidity during the heating process. Even when a much lower or a relatively higher temperature is used, there is really no problem in handling the aluminum and its alloys.

First of all, aluminum bears properties that react effectively in the welding process. It easily melts and then never cracks even after solidifying. The procedure of aluminum welding is performed depending on the aluminum parts types. Many of these parts are those that contain the so called commercial grade aluminum which are compacted with about 99% of purity. Therefore, the effects of the heat treatment vary as well. Those that have lead or copper in them are too hard to weld and usually end up cracking during the process of welding.

Secondly, the welding procedure of the aluminum parts types include the TIG and MIG along with the other traditional techniques of resistance welding, plasma, gas, and use of covered electrodes. TIG is the approach used in generating the fine surface finishes and in the welding of pipes and repairing the castings. Meanwhile, the MIG technique suits the welding of thicker aluminum metal pieces that require a longer welding cycle.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

The Best of Aluminum Die Casting Companies

The Best of Aluminum Die Casting Company. A lot of manufacturers always look for the best aluminum die casting company. Aside from their products needing a lot of aluminum die parts and components, the metalworking industry provides a variety of companies that offer the same type of service. Although competition may be tough and selections may come in great numbers, there is always the possibility of choosing the wrong company to execute your specific needs. A lot of sample companies have their own catalogs online that prospective customers may review and take note of. It is important to have an overall knowledge of the common rates and processes involving die casting prior to selecting your own aluminum die casting company.

The Best of Aluminum Die Casting Company. A lot of manufacturers always look for the best aluminum die casting company. Aside from their products needing a lot of aluminum die parts and components, the metalworking industry provides a variety of companies that offer the same type of service. Although competition may be tough and selections may come in great numbers, there is always the possibility of choosing the wrong company to execute your specific needs. A lot of sample companies have their own catalogs online that prospective customers may review and take note of. It is important to have an overall knowledge of the common rates and processes involving die casting prior to selecting your own aluminum die casting company.

Furthermore, such companies commonly provide intensive analysis of how their process is done. An ideal aluminum die casting company has a specific team for every step involved in the die casting process. These subdivisions allow better outputs of dies by use of well conducted design imports. The specific people who oversee the manufacturing system should also conduct quality control to provide consumers with the best products in accordance to their specific requests. Most dies require precise measurements that must be followed regardless of the number of items being requested. There are also die casting companies that specialize in complex pressure vessels as well as other difficult components. These are companies that have been around in the industry for quite some time and have mastered the entire process of aluminum die casting. Consumers must also be on the lookout for companies that have proven themselves throughout the years and have efficiently served the metalworking industry.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

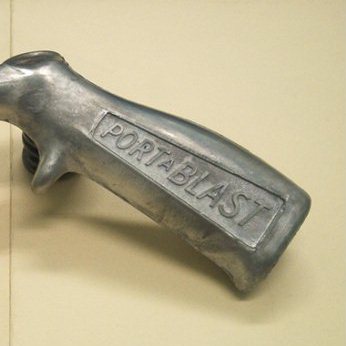

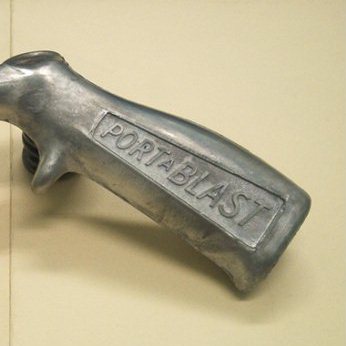

Manufactured Aluminum Hardware Handles

Manufactured Aluminum Hardware Handles. When it comes to manufacturing, one of the best metals to use in certain parts and products is aluminum. This metal is ideal because it is relatively easy to acquire, hence it is cheap. Companies can mine them almost everywhere. Not only is aluminum cheap, its characteristics are of high quality. This metal is comparable to steel when it comes to strength and durability. In terms of weight, aluminum is also significantly lighter than steel as well. This is why it is used in making hardware handles.

Manufactured Aluminum Hardware Handles. When it comes to manufacturing, one of the best metals to use in certain parts and products is aluminum. This metal is ideal because it is relatively easy to acquire, hence it is cheap. Companies can mine them almost everywhere. Not only is aluminum cheap, its characteristics are of high quality. This metal is comparable to steel when it comes to strength and durability. In terms of weight, aluminum is also significantly lighter than steel as well. This is why it is used in making hardware handles.

First of all, Aluminum Hardware Handles are designed so that it can take high amounts of punishment. It is used to be pulled, pushed, turned and takes much abuse in order to open doors and other entry ways. In using Aluminum Hardware Handles, manufacturers can be sure that it will last longer compared to other materials because of its characteristics. And by using die casting, they can also produce them faster and with better consistency.

Secondly, the manufacturing process known as die casting uses heat and pressure to make the parts or products, in this case, Aluminum Hardware Handles. The process starts with the raw aluminum, it is then subjected to an intense amount of heat in order to melt it. The liquefied metal is then injected into molds where its cavities give its shape. Using pressure of up to 30,000 PSI, the liquid metal is forced into every nook and cranny of the mold. After the mold cools down, the resulting Aluminum Handles have accurate dimensions, consistent and with great surface quality.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com