Aluminum Bracket Hardware – How are they Made? Brackets are used in many ways. Basically, their main purpose is to hold something in place. They are there so that something that shouldn’t move does not. When it comes to these …

Continue reading

Tag Archives: Diecasting Process

Different Types of Aluminum Castings

Different Types of Aluminum Castings. Aluminum die castings are used to by a lot of metalworking companies to form the perfect aluminum material, without having to spend a lot of money and wasting a lot of time. Due to the versatility of these processes, a lot of companies have turned to this unique way in forming one of the most dependable alloys that is used for several components in the same industry. There are a lot of items that were produced out of aluminum castings from the Washington Monument’s cap to the ancient tea kettles used by people who lived hundreds and hundreds of years ago. Although there have been a lot of improvements in the process of aluminum castings, most of the companies still resort to the traditional means of using molten metal to form some of the most intricate dies in history.

Different Types of Aluminum Castings. Aluminum die castings are used to by a lot of metalworking companies to form the perfect aluminum material, without having to spend a lot of money and wasting a lot of time. Due to the versatility of these processes, a lot of companies have turned to this unique way in forming one of the most dependable alloys that is used for several components in the same industry. There are a lot of items that were produced out of aluminum castings from the Washington Monument’s cap to the ancient tea kettles used by people who lived hundreds and hundreds of years ago. Although there have been a lot of improvements in the process of aluminum castings, most of the companies still resort to the traditional means of using molten metal to form some of the most intricate dies in history.

Furthermore, Aluminum castings can come in three diverse methods. Out of the three (permanent mold casting, sand casting and die casting), die casting is considered as the most popular among all companies in the metalworking industry. Although sand casting is known to be more versatile due to its delicate patterns, die castings prove to produce the most durable components used by a lot of automobile franchises and even the smallest of modern electronic gadgets. Other would say, however, that permanent mold castings also produce durable materials, but may need more expensive equipments and methodologies compared to the two other methods. Although these three processes may have a lot of differences, it can be agreed that aluminum die castings are highly effective in whichever method they are performed under.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Die Casting Tooling Inserts

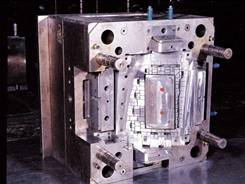

Die Casting Tooling Inserts. There are four types of die cast tools. These are: the single cavity die, the multiple cavity die, the unit die and the combination die. However, all of these dies may have one thing in common. These may be using smaller pieces of metals called inserts. With the advancement in the designing process, many of the more sophisticated die casting tooling can now be fabricated successfully using these smaller pieces of metal. Although these may look nothing more than thin rods of material or even a blob of metal (literally) inserted in the die, inserts are probably the best and most economical way of creating sophisticated cast die pieces.

Die Casting Tooling Inserts. There are four types of die cast tools. These are: the single cavity die, the multiple cavity die, the unit die and the combination die. However, all of these dies may have one thing in common. These may be using smaller pieces of metals called inserts. With the advancement in the designing process, many of the more sophisticated die casting tooling can now be fabricated successfully using these smaller pieces of metal. Although these may look nothing more than thin rods of material or even a blob of metal (literally) inserted in the die, inserts are probably the best and most economical way of creating sophisticated cast die pieces.

The main purpose of inserts is to create the holes or the running tubes within the piece. In earlier times, these holes or tubes can only be “placed” within a finished piece by manually or mechanically gouging it out. Needless to say, this can be a pricey affair especially if you consider the actual cost of hiring either skilled workmen to drill the holes or buying machines for the same purpose. Also this practice was subject to a lot of errors and therefore not feasible for mass production – especially when quality control is very rigid.

Fortunately, die cast tooling inserts can now be easily accommodated in most cast die machines. The material used for inserts depend on the actual materials being processed by the machines. As a rule hot chamber machines use molten materials with lower melting points like copper, lead, magnesium and even zinc. On the other hand, cold chamber machines use mainly aluminum or aluminum based alloys which have higher melting points. The inserts are made from the same materials as the actual die, usually steel alloys, but these are reinforced to make sure that metal erosion does not take place during the actual production stage.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Lighting Fixtures–Die Casted

Aluminum Lighting Fixtures–Die Casted. The die casting manufacturing process is quite similar to permanent mold casting. Both processes start out by melting or liquefying the material such as resin, rubber, zinc, copper and aluminum to name a few, that is going to be used. The melted materials will then be injected into die cast molds castings. The liquid will then take the form of the patterns in the mold castings. The molds will then be allowed to cool down to harden and once they are opened, the product is finished. The difference between die casting and permanent mold casting is that the former uses high amounts of pressure in the molds so that the material will get into every part of the pattern. This results in better quality of the products which is why die casting is chosen to make Aluminum Lighting Fixtures.

Aluminum Lighting Fixtures–Die Casted. The die casting manufacturing process is quite similar to permanent mold casting. Both processes start out by melting or liquefying the material such as resin, rubber, zinc, copper and aluminum to name a few, that is going to be used. The melted materials will then be injected into die cast molds castings. The liquid will then take the form of the patterns in the mold castings. The molds will then be allowed to cool down to harden and once they are opened, the product is finished. The difference between die casting and permanent mold casting is that the former uses high amounts of pressure in the molds so that the material will get into every part of the pattern. This results in better quality of the products which is why die casting is chosen to make Aluminum Lighting Fixtures.

Also, Aluminum Lighting Fixtures help in illuminating man made structures such as houses, buildings, tunnels as well as the streets at night. They are an essential part of these structures and a lot of them are needed. By using the die casting process, the bulk orders for these Aluminum Lighting Fixtures are met. Not only that, quality and consistency is insured by die casting. This is a cost efficient and effective way of producing Aluminum Lighting Fixtures.

Furthermore, Aluminum is a great choice for lighting fixtures as they are strong and can last a very long time. They are also very lightweight compared to other metals. Since they can be harvested almost anywhere, they are very cheap too.

Light Fixture Die Casting Parts

Kinetic Die Casting Company makes aluminum die castings as Lighting Fixture Die Castings. We make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

The Alloys of Die Casting

The Alloys of Die Casting. Aluminum is one of the most common alloys used in die casting. Aluminum is also one of the many alloys that can undergo almost all the process in casting. Die casting is where the aluminum is mostly used. But pure aluminum casting is rarely produced because of the susceptibility of the alloy to cracking and shrinkage. This alloy is usually alloyed with silicon and copper because these two alloys can increase melt fluidity, especially silicon, and reduces ductility. Silicon can also reduce maintainability of the alloy and copper can increase the hardness. The combination of the three alloys can reduce corrosion. For better corrosion resistance, aluminum casting with lower copper should be used such as 360 and 413. Aluminum is also commonly used when it comes to electricity because of its conductivity and high temperature strength. Aluminum has many uses in today’s everyday lives from office to home to commercial uses and industrial uses.

The Alloys of Die Casting. Aluminum is one of the most common alloys used in die casting. Aluminum is also one of the many alloys that can undergo almost all the process in casting. Die casting is where the aluminum is mostly used. But pure aluminum casting is rarely produced because of the susceptibility of the alloy to cracking and shrinkage. This alloy is usually alloyed with silicon and copper because these two alloys can increase melt fluidity, especially silicon, and reduces ductility. Silicon can also reduce maintainability of the alloy and copper can increase the hardness. The combination of the three alloys can reduce corrosion. For better corrosion resistance, aluminum casting with lower copper should be used such as 360 and 413. Aluminum is also commonly used when it comes to electricity because of its conductivity and high temperature strength. Aluminum has many uses in today’s everyday lives from office to home to commercial uses and industrial uses.

Furthermore, Aluminum Die Casting also has high dimensional stability when doing complex shapes and thin walls. The typical applications of aluminum alloy are Alloy 380.0, A380.0, 360, 413, and 518.1. They are typically used for home equipment like lawnmower, dental equipment, street lamp housings, frying skillets, escalator parts, connecting rods, instrument cases, and marine and aircraft hardware. Alloy 518 is known to have the highest corrosion resistance but it has low fluidity compared to the other aluminum alloys. This is also usually the most expensive aluminum alloy because of the difficulty to cast.

Also, Aluminum casting usually doesn’t undergo heat treatment but instead undergo metallurgical stabilization and dimensional treatment.

Aluminum Heat Sinks are Die Casted

Aluminum Heat Sinks are Die Casted. Aluminum Heat Sinks have one important purpose, and that is to regulate heat generated by the product it is in. These heat sinks are placed in most electronics and appliances so that the heat from electrical wiring and other parts of the product are diverted from them into the heat sink, thus protecting them from overheating and malfunctioning. In other words, Aluminum Heatsinks provide a very important safety feature for these products. This means that throughout its life span, it will take on a lot of abuse and beating, which is why aluminum is ideal for the job.

Did you know that aluminum is a very tough and durable material? It has been noted that it is comparable to steel in terms of durability. But, when it comes to weight, aluminum weighs just a third of steel of the same size and shape. This makes it ideal for making heat sinks. Also, aluminum can be harvested almost anywhere in the world. This means that it is cheap and easy to acquire. To meet high demands for Aluminum Heat Sinks, the manufacturing process known as die casting is used.

Furthermore, the first step in die casting Aluminum Heatsinks is to liquefy the aluminum bars that are going to be used. Once in their liquid state, they will then be injected into casting molds. These castings give the liquid its new shape. Then, pressure of up to 35,000 pounds per square inch/PSI is applied on the castings. This will let the liquid set in every part of the die cast mold. It will then be set aside to cool and harden. Once opened, the product only requires a few finishing touches and its done.