The Advantages of Aluminum Heat Sinks Die Castings over Plastic. The heat sinks are important components in any electronic product. Airplanes, computers, communication companies, automobiles, and lightings rely on this product to remove the heat from most of their parts. …

Continue reading

Tag Archives: Diecasting Process

The Best of Aluminum Die Casting Companies

The Best of Aluminum Die Casting Company. A lot of manufacturers always look for the best aluminum die casting company. Aside from their products needing a lot of aluminum die parts and components, the metalworking industry provides a variety of companies that offer the same type of service. Although competition may be tough and selections may come in great numbers, there is always the possibility of choosing the wrong company to execute your specific needs. A lot of sample companies have their own catalogs online that prospective customers may review and take note of. It is important to have an overall knowledge of the common rates and processes involving die casting prior to selecting your own aluminum die casting company.

The Best of Aluminum Die Casting Company. A lot of manufacturers always look for the best aluminum die casting company. Aside from their products needing a lot of aluminum die parts and components, the metalworking industry provides a variety of companies that offer the same type of service. Although competition may be tough and selections may come in great numbers, there is always the possibility of choosing the wrong company to execute your specific needs. A lot of sample companies have their own catalogs online that prospective customers may review and take note of. It is important to have an overall knowledge of the common rates and processes involving die casting prior to selecting your own aluminum die casting company.

Furthermore, such companies commonly provide intensive analysis of how their process is done. An ideal aluminum die casting company has a specific team for every step involved in the die casting process. These subdivisions allow better outputs of dies by use of well conducted design imports. The specific people who oversee the manufacturing system should also conduct quality control to provide consumers with the best products in accordance to their specific requests. Most dies require precise measurements that must be followed regardless of the number of items being requested. There are also die casting companies that specialize in complex pressure vessels as well as other difficult components. These are companies that have been around in the industry for quite some time and have mastered the entire process of aluminum die casting. Consumers must also be on the lookout for companies that have proven themselves throughout the years and have efficiently served the metalworking industry.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

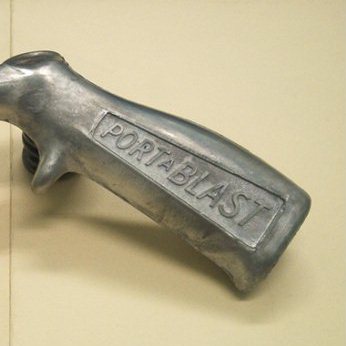

Manufactured Aluminum Hardware Handles

Manufactured Aluminum Hardware Handles. When it comes to manufacturing, one of the best metals to use in certain parts and products is aluminum. This metal is ideal because it is relatively easy to acquire, hence it is cheap. Companies can mine them almost everywhere. Not only is aluminum cheap, its characteristics are of high quality. This metal is comparable to steel when it comes to strength and durability. In terms of weight, aluminum is also significantly lighter than steel as well. This is why it is used in making hardware handles.

Manufactured Aluminum Hardware Handles. When it comes to manufacturing, one of the best metals to use in certain parts and products is aluminum. This metal is ideal because it is relatively easy to acquire, hence it is cheap. Companies can mine them almost everywhere. Not only is aluminum cheap, its characteristics are of high quality. This metal is comparable to steel when it comes to strength and durability. In terms of weight, aluminum is also significantly lighter than steel as well. This is why it is used in making hardware handles.

First of all, Aluminum Hardware Handles are designed so that it can take high amounts of punishment. It is used to be pulled, pushed, turned and takes much abuse in order to open doors and other entry ways. In using Aluminum Hardware Handles, manufacturers can be sure that it will last longer compared to other materials because of its characteristics. And by using die casting, they can also produce them faster and with better consistency.

Secondly, the manufacturing process known as die casting uses heat and pressure to make the parts or products, in this case, Aluminum Hardware Handles. The process starts with the raw aluminum, it is then subjected to an intense amount of heat in order to melt it. The liquefied metal is then injected into molds where its cavities give its shape. Using pressure of up to 30,000 PSI, the liquid metal is forced into every nook and cranny of the mold. After the mold cools down, the resulting Aluminum Handles have accurate dimensions, consistent and with great surface quality.

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Brackets. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

The Disadvantages of having Porosity in Die Casting

Disadvantages of porosity in diecasting. Diecasting is a method of molding molten metal, plastic and resin into whatever shape you desire. In order to do this, a machine will need to pour the molten substance into a container and then force it inside the mold until it cools down. The substance will eventually harden and take the form of the die cast mold it is in. Die casting is commonly used in making toys, instruments, costumes and even costumes. However, there are certain problems in which the products become porous which contributes a lot to its brittleness. This is commonly known as die cast porosity, an unwanted result brought about by air pockets and void space inside the molded material. Products with porosity typically are considered to be of low standard and poor in quality. Here are some disadvantages of die casting porosity.

Disadvantages of porosity in diecasting. Diecasting is a method of molding molten metal, plastic and resin into whatever shape you desire. In order to do this, a machine will need to pour the molten substance into a container and then force it inside the mold until it cools down. The substance will eventually harden and take the form of the die cast mold it is in. Die casting is commonly used in making toys, instruments, costumes and even costumes. However, there are certain problems in which the products become porous which contributes a lot to its brittleness. This is commonly known as die cast porosity, an unwanted result brought about by air pockets and void space inside the molded material. Products with porosity typically are considered to be of low standard and poor in quality. Here are some disadvantages of die casting porosity.

Air pockets inside a die cast product; can cause weakness of the material. The structure becomes less stable because the density of the particles melded together is not balanced due to small voids of space within. There are also times when die casting porosity makes the product look less appealing to the buyer or consumer, due to the impression that porosity is a result of low quality machine and materials. Chances of infiltration are also high due to an imbalance in the density of the material. Luckily, there are a lot of ways to reduce the chances of cast die porosity. However, it would also mean an increase in your expense, but it would also increase the chance of more consumers because of your high grade product materials.

Kinetic Die Casting Company makes aluminum die castings using Die Casting Tooling. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

The Best Aluminum Die Cast Companies

The Best Aluminum Die Cast Companies. Finding the best aluminum die casting company is a challenge, especially for someone who is relatively new in the business. Due to the successful parts and other outputs made from aluminum die casting, a huge number of companies began sprouting from all corners of the earth claiming to provide the best quality service. Although advertisements can be pleasing to the consumers’ eyes, there are a lot of things that need to be considered when seeking the ideal company to work with your die casting needs. When looking for that perfect aluminum die casting company, you must be able to check if the prices are well fared and if the products of their company are assured of quality. There are different types of die casting and without any knowledge of the basic process involving the products’ construction, you may end up signing a deal with the wrong company.

The Best Aluminum Die Cast Companies. Finding the best aluminum die casting company is a challenge, especially for someone who is relatively new in the business. Due to the successful parts and other outputs made from aluminum die casting, a huge number of companies began sprouting from all corners of the earth claiming to provide the best quality service. Although advertisements can be pleasing to the consumers’ eyes, there are a lot of things that need to be considered when seeking the ideal company to work with your die casting needs. When looking for that perfect aluminum die casting company, you must be able to check if the prices are well fared and if the products of their company are assured of quality. There are different types of die casting and without any knowledge of the basic process involving the products’ construction, you may end up signing a deal with the wrong company.

Furthermore, an aluminum die casting company focuses primarily on making aluminum die cast parts. Through this process, different types of machinery and equipments are used to provide you with your desired output. Check for the company that has the best equipments at hand to aid in creating your ordered parts. Molten aluminum alloy metal is being used to provide you with the best devices for your automotive ventures and construction work. There are companies that may not necessarily use aluminum alloy die casting and may resort to zinc alloy. Knowing the difference of these materials’ robustness and longevity may also affect your decision in choosing the right company to execute your plans.

Kinetic Die Casting Company makes Aluminum Casting Parts. As a die casting company, we make these parts every day and ship thousands of these aluminum die castings every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Die Casting–What You Need to Know. The manufacturing process involved in aluminum die casting is roughly the same as that used in the production of pre-fabricated concrete building materials such as the hollow blocks that commonly go into the construction of houses. The big difference of course is in the material used. Water, cement and aggregates such as gravel and sand are used In pre-fabricated concrete, while in aluminum die casting, molten aluminum is the base material.

Aluminum Die Casting–What You Need to Know. The manufacturing process involved in aluminum die casting is roughly the same as that used in the production of pre-fabricated concrete building materials such as the hollow blocks that commonly go into the construction of houses. The big difference of course is in the material used. Water, cement and aggregates such as gravel and sand are used In pre-fabricated concrete, while in aluminum die casting, molten aluminum is the base material.