How are Aluminum Golf Products used? Aluminum is now being used in different fields of work and leisure. It has use in heavy industries such as construction and in highly mechanized fields like astronomy and militia. At the same time, …

Continue reading

Tag Archives: Handles

Die Casting Crafting Excellence

Die Casting’s Role in hardware manufacturing, where precision, durability, and reliability are paramount, die casting emerges as a game-changer, offering unmatched versatility, efficiency, and quality. From door handles and hinges to cabinet knobs and tool components, die casting plays a pivotal role in crafting hardware parts that meet the exacting standards of the industry. Let’s delve into the significance of die casting in hardware manufacturing and explore how it drives innovation and excellence in this dynamic sector. Hardware parts serve as the backbone of countless products and systems, providing essential functionality and structural support. Die casting enables the production of hardware parts with intricate geometries, tight tolerances, and complex features, ensuring optimal performance and reliability. Whether it’s ensuring smooth operation in door mechanisms, precise alignment in cabinet hardware, or robust functionality in tool components, die casting delivers the precision engineering required for functional hardware parts.

Die Casting Hardware parts are subjected to constant wear and tear, requiring superior strength and durability to withstand the rigors of daily use. Die casting, utilizing materials such as zinc and aluminum alloys, produces hardware parts with exceptional mechanical properties, including high tensile strength, impact resistance, and corrosion resistance. From outdoor fixtures enduring harsh weather conditions to heavy-duty tools and equipment with demanding usage requirements, die-cast hardware parts offer longevity and reliability, ensuring years of dependable performance.

In addition to functional performance, aesthetics play a significant role in hardware design, enhancing the overall appeal and visual impact of products and spaces. Die casting offers unparalleled design flexibility, allowing for the creation of hardware parts with intricate details, decorative finishes, and customizable features. Whether it’s ornate door handles, sleek cabinet pulls, or stylish furniture hardware, die-cast parts can be tailored to complement any design aesthetic, adding a touch of sophistication and elegance to the finished product. Efficiency is a cornerstone of successful manufacturing, and die casting excels in delivering high-quality hardware parts with optimal efficiency and cost-effectiveness. The die casting process enables rapid production cycles, with the ability to produce large volumes of parts in a relatively short time-frame. Additionally, die casting minimizes material waste and secondary processing requirements, resulting in cost savings and streamlined production workflows. Whether it’s mass production of standardized components or custom fabrication of unique hardware solutions, die casting offers a competitive edge in terms of efficiency and economics.

Die Casting Quality is non-negotiable in hardware manufacturing, where product failure can have significant consequences in terms of safety, performance, and reputation. Die casting companies prioritize quality assurance at every stage of the manufacturing process, from material selection and tooling design to production control and post-casting inspection. Utilizing advanced quality control measures, such as dimensional analysis, metallurgical testing, and visual inspection, die casting ensures that every hardware part meets the highest standards of quality and reliability, instilling confidence in customers and end-users alike.

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Hardware Parts:

Quote Prices Die Casting Hardware Parts

Kinetic Die Casting Company makes:

Die Casting Handle Hardware

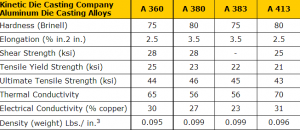

Die Casting Alloys

Die Casting Aluminum Alloys

Permalink: https://www.kineticdiecasting.com/kdc/die-casting-crafting-excellence/

#Hardware, #Brackets, #Handles, #Kineticdc, #Diecasting, #DiecastingParts, #DiecastHardware, #KineticDieCastingCompany, #DieCastingCompany, #Diecast, #Manufacturing, #California

Kinetic Aluminum Handles

Kinetic Die Casting Makes Aluminum Handle Hardware. Handle hardware refers to door and cabinet handles, which need to be able to withstand constant pushes and pulls. When it comes to handle hardware, aluminum is one of the best materials to use when manufacturing handles. Aluminum is strong, durable, and sturdy, and is perfect for ensuring that handle hardware will last despite long-term abuse. Additionally, aluminum is lightweight and cheap, so buying and installing aluminum handle hardware does not burn a hole in customers’ pockets.

Die Casting Aluminum Alloys

Die casting is the best and most reliable method to quickly produce aluminum handle hardware in large quantities. The method involves creating a cast or a mold first to resemble the shape of the handle to be produced. Afterwards, the aluminum is subjected to intense heat so that it becomes liquid. The liquefied metal is then injected into the cast or mold for the aluminum to take the mold’s shape. The mold with the aluminum is then cooled to let the liquid metal set and harden into the new shape. When the aluminum has hardened, the mold is then opened to reveal new aluminum handles. In North Hollywood, California, there is a company called the Kinetic Die Casting Company that specializes in various die-cast parts and products, such as automotive parts, enclosures and housings, aluminum lighting fixtures, and aluminum handle hardware. The company’s website not only showcases its products but also has pages that explain what aluminum handle hardware parts are, what the advantages are of using aluminum for handles, and how to choose the right handle hardware.

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Permalink: https://www.kineticdiecasting.com/kdc/kinetic-aluminum-handles/

Kinetic Die Casting utilizes die casting to manufacture parts like aluminum car parts, airplane parts, lighting parts and much, much more. If you would like to request a quote, please visit our website:Die Casting quote