I had lunch today with the owner of a die casting company who expressed an interest in selling his die casting company. He does not want to sell his company but he may need to sell it if his sales …

Continue reading

Tag Archives: Video

Diecast Enclosures 2019

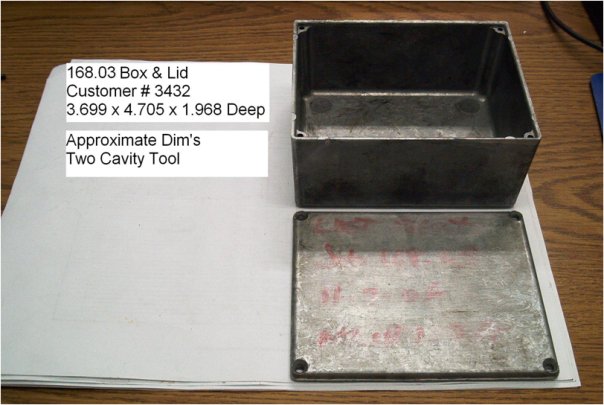

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum enclosures through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a steel die casting mold tool. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the enclosures are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Enclosures. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting parts every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Heatsink Metal Flow Video

Kinetic Die Casting Company (www.kineticdc.com) uses metal flow software to check die casting tooling metal flow into a die casting mold making two cavities of a Heat Sink Part

(Metal Flow into Mold or Die Casting Tooling).

This is an Aluminum Heat Sink Die Casting Part for the lighting industry.

Permalink: https://www.kineticdiecasting.com/kdc/heatsink-metal-flow-video/

Two cavity aluminum heat sink die casting molds. This 5 seconds of video happens in a small fraction of a second as the metal is injected under extreme pressure. The metal flows very rapidly into a die casting mold using 2,000 pounds per square inch of hydraulic pressure that is accelerated in high shot assisted by 700 pounds of high pressure nitrogen gas inside a die casting machine.

818-982-9200 (music provided by YouTube)

Kinetic Die Casting Company

E-mail sales@kineticdc.com / 818-982-9200 / 800-524-8083 Toll Free / 818-982-0877 Fax

6918 Beck Avenue, North Hollywood, California USA 91605,

Kineticdc makes: Die Casting Parts Aluminum Heat Sinks

What People Don’t Know About Die Casting Tooling

What People Don’t Know About Die Casting Tooling. Aluminum Lighting Fixtures use die casting tooling. Tooling is also known as insert die or casting molds which may come in several different sizes and styles. It is the forming of tools via die casts. It may cost from hundreds of dollars up to thousands depending on the size of the total die cast package. The least costly type of die cast tooling is the die cast inserts. These high pressure die cast inserts are collected basically of the minimum amount of steel essential to manufacture the cavities with a tad bit extra in order to have some allowance for temperature fluctuations. At times nevertheless, this may be hard to achieve as the right density is necessary. If it is too hard, the steel will break due to the high temperature, if the cavities are too yielding, they will wear away rapidly from the molten metal.

In order to first test out the weight and worth of the tool without placing much cost in making an genuine die cast tool, one is suggested to create a prototype die casting tooling insert. This relates in comparable ways to the die cast tooling not including that cheaper metals are utilized and are not heat treated to reduce costs. This is chiefly done to test a design. Clearly it has numerous downsides such as the reduced durability of the tool.

As shown above, there are numerous ways to save hundreds of dollars in die casting tooling. In taking into account the size, assuring the right density of the cavities and by first producing a prototype to test the design before mass producing the die casts, much money can be collected.

Kinetic Die Casting Company can manufacture aluminum car parts, aluminum hardware, and Aluminum Lighting Parts 818-982-9200

http://www.youtube.com/user/kineticdc

Kinetic Die Casting First Metal Flow Video

This Video of the aluminum alloy metal flow into a die casting mold to produce an Aluminum Heat Sink used in an Aluminum Lighting Fixture

Kinetic Die Casting Company www.kineticdc.com uses software to check the metal flow into into this Heat Sink Die Casting Mold. This Metal Flow video shows the metal flowing into the die casting Mold or Die Casting Tooling. Aluminum Heat Sinks like this one are used in the lighting industry. This video shows a two cavity die casting mold. Call us today at 818-982-9200

- Where Aluminum Lighting fixtures Are Used:

- Medical offices use hanging light fixtures.

- Parking garage lighting fixture housings.

- Bullet light fixture.

- Street traffic light housings.

- Walk light housings.

- High temperature light housings.

- Outdoor coach lights.

- Wall sconse fixtures.

Check out Kinetic Die Casting on our Facebook page:

Like Kineticdc Facebook

Call us when you need a lighting fixture part made in aluminum. We will be happy to tell you if you can save money using the die casting process.

Call 818-982-9200 or Email sales@kineticdc.com

Video of Auto Parts at Kinetic Die Casting Company

Automotive Die Casting Parts from

Kinetic Die Casting Company

Kinetic Die Casting Company makes several auto parts for our customers. This automotive parts video shows a few of the automotive parts we produce for our customers. On our website, we show other pictures of automotive parts. Aftermarket car parts manufacturers depend on companies like Kinetic Die Casting to help with the design of the part and produce auto parts at a competitive price.

Aluminum auto parts in this video are produced from a few parts to thousands of car parts a day. Many features of the automotive part are manufactured “near net shape” to save the cost of wasted materials and the additional labor of machining. Mounting holes are usually produced into the aluminum auto part during production. also saving cost. Many of the primary “tier one” automotive manufacturers have their own manufacturing plants. They also purchase aluminum automotive parts from companies such as Kinetic Die Casting Company.

Contact Kinetic Die Casting Company today if you need an automotive part in aluminum or zinc. We are located just north of Los Angeles, California at 6918 Beck Avenue, North Hollywood 91605.

Call 800-524-8083 or Email at sales@kineticdc.com