The advantages of Aluminum Handle Hardware over plastic. Aluminum handles are probably the most common aluminum product that we use and see in our everyday lives. From door handles to cabinet handles, to handles used for carrying electronic devices and …

Continue reading

Tag Archives: Zinc Die Casting

2023 Die Castings Summer Sale

July 25, 2023 – Attention diecasting customers. 07/25/23 to 08/31/23 a $10 Starbucks Gift Card for new POs.

Kinetic Die Casting Company‘s die casting machine production typically slows down for summer months. We currently have more time in our die casting machines for production over the next few months. Our customers will get a free ten dollar ($10) Starbucks Gift Card for any new purchase order placed between July 25th to August 31st. Hopefully, you will want us to produce your die casting parts and ship your parts within the next three months.

As a reminder, we work Monday through Thursday. We make aluminum die casting parts and zinc die casting parts. Thank you for your business!

Please send your new purchase orders to sales@kineticdc.com. Thank you for being our loyal customer. We have been making die casting parts almost 30 years, since 1994.

Kinetic Die Casting Company, Inc.

6918 Beck Avenue, North Hollywood, CA 91605

818-982-9200

Permalink: https://www.kineticdiecasting.com/kdc/2023-die-castings-summer-sale/

Die Casting Zinc Alloys in 2022

Die Casting Zinc Alloys

Die casting zinc alloys to offer castability, a broad range of excellent physical and mechanical properties, and finishing characteristics. The advantages of utilizing zinc alloys include thin walls, close dimensional tolerances, and variation in section design. Compared to others, die-casting zinc alloys have higher strength components.

The die maintenance is reduced and the die life is lengthened because of the lower temperatures under which zinc alloy is cast. There are several companies that manufacture a complete range of die-casting zinc alloys. One of them is the Eastern Alloys.

Die casting zinc alloys have high strength and hardness, which makes them ideal alternatives for machined, pressed, stamped, and fabricated items. Normally cast alloys are non-ferrous and there is a large number available with a wide range of physical and mechanical properties covering almost every conceivable application a designer might require. Die casting zinc alloys are among the most widely used because of their low melting point. Usually, low melting point alloys are cast in a hot chamber machine while intermediate and high melting alloys are cast in cold chamber machines.

One of the fastest and most cost-effective methods for producing a wide range of components is die casting. The major benefit from this process can be achieved if the designers were able to collaborate with the die caster at an early stage of product development and design. In order to help resolve issues that affect the tooling and production during the design phase, it is best to consult the die caster at the earliest possible time.

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes:

Die Casting Zinc Automobile Parts 2021

Useful Information about Die Casting Zinc Automobile Parts. Manufacturing automobiles normally include die casting zinc automobile parts. An automobile is composed of thousands of parts, countless of which are manufactured from zinc. Zinc may also be joined with other alloys to attain detailed purposes. There are useful reasons why die castings is done for manufacturing cars and other four-wheeled vehicle parts:

• Cars are mass manufactured and need many mechanisms; die casting is a fast yet dependable technique to generate metallic parts for them

• Die casting is multipurpose and has the prospective to make parts in changeable shapes and sizes

• The subsequent goods are sturdy and very long-lasting

• It’s inexpensive to die cast car parts likened to other forms of production

• Die casts are readily recyclable and non-toxic

Zinc is an outstanding choice of alloy for constructing auto parts because it is unbending, hard, small, lightweight, non-sparking, and not corrosive. The bulk of vehicles have zinc parts in them because they perform well and are low-priced to produce. Here are some uses of die casting zinc automobile parts:

• For shielding electronic components

• For enclosing airbags, sensors, telematics, switches, and other sensitive equipment

• For constructing solid items, such as lock barrels, seat belts, etc.

• For ornamental purposes – metal platings, finishes, and designs

Though die casting zinc automobile parts is an acclaimed procedure, the quality shaped still be contingent on what the manufacturer does. When buying auto parts, search for a die caster with a decent track record of creating quality parts that have passed difficult testing.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” https://www.kineticdiecasting.com/replyform.html

Die Casting Auto Parts

Die Casting Car Parts

Manufacturing Die Casting Parts

Aluminum Die Casting Company

Photos Die Casting Car Parts

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

We put the parts in poly bags, pad the parts and boxes.We put the parts in poly bags, pad the parts and boxes. Toll Free: (800) 524-8083 Local: (818) 982-9200 E-mail sales@kineticdc.com

Die Casting Automotive Parts Prices

Diecastings Made 2017

Kinetic Die Casting Part Types in 2017:

Die Casting Military Parts.

Die Cast Heater Plates.

Aluminum Heat Sinks Die Castings.

Golfing Products.

Cast Aluminum Golf Products.

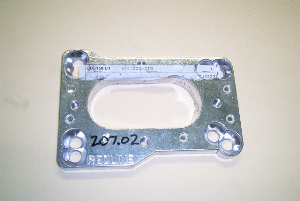

Aluminum Handle Hardware.

Aluminum Chassis Castings.

Cast Aluminum Parts for Music.

Aluminum Hardware Brackets.

Aluminum Automotive Parts.

Cast Aluminum Lighting Parts.

Aluminum Lighting Fixture Parts.

Aluminum Speaker Parts.

Roofing Tilemolds.

Cast Aluminum Rooftile Molds.

Aerospace Die Castings.

Cast Aluminum Boxes.

Aluminum Aircraft Parts.

Die Casting Company.

Images Pictures Die Cast Parts.

Answers for Diecastings.

Kinetic Die Casting Company Blog.

Die Casting Tools Molds .

Kinetic Die Casting Company.

Permalink: https://www.kineticdiecasting.com/kdc/diecastings-made-2017/

PORT-A-BLAST Sand Blast Gun

This newsletter is a guest posting from our customer. Perfect for all of your portable sandblasting needs. The PORT-A-BLAST sand blast gun is a complete sand blast unit. Fill the container with the abrasive material needed for the project. Connect the gun to your air supply. 60 to 150 P.S.I. will work. We recommend 100 to 150 P.S.I. pressures for quicker and better results. The greater the pressure the faster the cutting. Now you are ready to go. Be sure that the operator is wearing both eye (goggles) and nose (respiratory mask) protection. Continuous abrasive dust inhalation (especially silica dust) can be harmful. For larger projects the gun can be used to siphon abrasives or liquids from a hopper or bucket with the use of a flexible siphon tube and eliminating the one quart container.

The PORT-A-BLAST is a very reliable and sturdy tool. It is built to give long continuous service. It has been manufactured in the US for over 30 years with users still using their original gun. In order for the user to properly care for the unit and prevent damage to the zinc cast body the inner end of the nozzle and the outer end of the jet need to be examined periodically. (At least once a day under continuous use.) When the nozzle is worn to approximately 1/16” wall thickness it should be replaced. The jet should be replaced when it wears enough to cut into the air hole. In addition to the nozzle and jet, all of the other PORT-A-BLAST parts and accessories are available for replacement or expanded function.

E-mail: admin@portablast.com

WWW.PORTABLAST.COM

Phone: 800 453-0386

Fax: 562 425-3839

This newsletter is a guest posting from our customer.

Please consider a visit to his website and purchasing his products.

Kinetic Die Casting Company (www.kineticdc.com)

6918 Beck Avenue North Hollywood Ca 91605

sales@kineticdc.com

Permalink: https://www.kineticdiecasting.com/kdc/port-a-blast-sand-blast-gun/