|

Material Characteristics

Compare Polycarbonate to A380 Aluminum alloy |

Characteristic

|

Polycarbonate |

A380 Aluminum Metal |

| Tensile strength |

55-75 MPa / 11 ksi |

317 MPa / 46 ksi |

| Melting Temperature |

267 C / 513 F |

595 C / 1100 F |

Density (weight) kg/m cube |

1220 kg/m cube |

2740 kg/m cube |

|

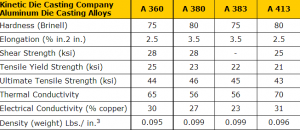

Die Casting Aluminum Alloys

Die Cast Aluminum Metal Parts compare well with Plastic Injection Molded Parts

in these areas:

- Plastic is an insulator. Aluminum die cast parts are electrically conductive benefitting manufacturers. Plastic needs a special coating or needs to be impregnated with metal particles to achieve a similar but inferior result.

- Plastic does not ground. Metal enclosures and housings are easily grounded. Plastic needs additional grounding "metal" straps.

- Plastic does not block RF. Aluminum Die Cast Enclosures are a natural shield for RF and EMI. They help prevent radio frequency.

- Compare Plastic Parts to die Casting Parts

Plastic Injection Moldings

- Plastic Injection Moldings are weaker than aluminum parts. Compared with plastic injection moldings, die castings are stronger.

- Plastic Injection Moldings are too flexible for many applications. Die Cast Aluminum parts are more stiffer.

- Plastic Parts are not very dimensionally stable. Aluminum parts are more stable dimensionally.

- Plastic injection molded parts do not generally do well in hot conditions. Aluminum is more heat resistant.

- Plastic does not fare well with many coatings. Aluminum parts are far superior to plastics on a properties/coat basis.

- Plastic injection molding does not block radio frequency.

- Plastic does not block electromagnetic emissions.

- Plastic injection molded parts do not lend themselves easily for chrome plating.

- Die castings have a high degree permanence under load compared to plastics.

- Die Cast Parts are completely resistant to ultra-violet rays.

- Die Cast Parts are completely resistant to weathering.

- Die Cast Parts are completely resistant to stress-cracking in the presence of various reagents.

- Manufacturing cycles for producing die castings are much faster than for injection moldings.

Recyclability

Plastic Parts

The non-metallic portion of a product is generally regarded by recyclers as "fluff," consisting mostly of plastic. Nearly one-quarter of all solid waste is estimated to be plastic, and less than 3% of this plastic is being recycled.

Problems with plastic product recyclability were brought up by a national task force, which requested that plastics marketers refrain from using the universal symbol for recycling in advertisements, since it was regarded as misleading in relation to plastics.

Aluminum Cast Metal Parts

Nearly all metals — and die castings in particular — have always been readily recyclable. Die castings are not hazardous waste and pose no problems in handling or reprocessing, as do some toxic non-metallics.

Die castings are recyclable components with engineering advantages not available in other metalforming processes. The major cost and performance benefits of parts consolidation possible with plastic components can be carried forward in die casting designs with additional advantages.

Net-shape die castings can be produced with thinner walls than comparable plastic parts, and can provide greater strength

and product durability over a longer life cycle — with added serviceability.

Die Castings Recycling Circle -Aluminum die casting alloy recycling has been in place almost from the beginning of custom die casting production.

Specifications for aluminum alloys have been developed that provide for a full range of compositions that can utilize various types of recycled metal. Carefully engineered and spectrographically controlled formulas result in precise specification ingot for each of the commonly used die casting alloys.

Over 95% of the aluminum die castings produced in North America are made of post-consumer recycled aluminum.

Since the production of recycled aluminum alloy requires approximately 5% as much energy as primary aluminum production, there is a dramatic conservation of non-renewable energy resources.

Die castings, as opposed to forgings or extrusions, for example, can make far greater use of recycled material. In selecting materials and manufacturing processes to meet consumer concerns, the product designer should ask these questions:

- Does the material allow for efficient and economical maintenance, repair, refurbishing or remanufacturing of the product to extend its life, where this is a design benefit?

- Is the material non-toxic and readily recyclable at the end of its useful life?

- Can the material be recovered and reused in high performance applications?

- Is the necessary infrastructure in place to make recycling of the reclaimed material a practical reality?

|

The advantages of Aluminum Audio Speaker Parts over Plastic in 2023

|

The advantages of Aluminum Audio Speaker Parts over plastic. If you are to match aluminum audio speaker parts against plastic audio speaker parts, which do you think is better? First of all, the first thing that you will notice with …

Continue reading »

|

|

Die Casting Supervisor Job August 2023

|

08/10/2023 – For nearly 30 years, Kinetic Die Casting Company has been a small manufacturing company located in the Los Angeles, California area. We make aluminum die casting parts and zinc die casting parts for our manufacturing customers. We are …

Continue reading »

|

|

A Comparison: Die Cast Parts or Plastic Parts in 2023

|

A Comparison: Die Cast Parts or Plastic Parts. Within the past decade, plastic molded products have become plentiful in the market. More and more plastic products are being shaped as extra to metal products such as faucet, door knobs, and …

Continue reading »

|

|

Die Cast Manager Job

|

Kinetic Die Casting Company, Inc. has a position available for a Die Casting Manager Job. This person will supervise production processes, housekeeping, enforce our safety policies and plant rules for the Die Cast department. Job duties may include supervising or …

Continue reading »

|

|

The Advantages of Aluminum Hardware Brackets over Plastic

|

Advantages of Aluminum Hardware Brackets over Plastic: Plastic is an insulator, while aluminum is electrically conductive. Plastic will need a special coating to achieve a similar result with aluminum (albeit inferior). Plastic does not ground, thus it requires extra grounding …

Continue reading »

|

|

The Advantage of Aluminum Lighting Parts over Plastic in 2021

|

The advantages of Aluminum Lighting Parts over plastic. With the invention of plastic, a lot of materials are being replaced for it. From wood to metal, each and every kind of instrument has a plastic equivalent. Because of the cost …

Continue reading »

|

|

The Advantages of Aluminum Military Parts over Plastic in 2021

|

The Advantages of Aluminum Military Parts over Plastic. Being in the military force is a life-threatening job. Together with this risk is the honor of saving one’s territory, which is one of the reasons why a number of men choose …

Continue reading »

|

|

The Advantages of Aluminum Military Parts over Plastic 2021

|

The Advantages of Aluminum Military Parts over Plastic. Being in the military force is a life-threatening job. Together with this risk is the honor of saving one’s territory, which is one of the reasons why a number of men choose …

Continue reading »

|

|

The Advantages of Cast Aluminum Parts for Music over Plastic Parts in 2021

|

The Advantages of Cast Aluminum Parts for Music over Plastic Parts. For serious musicians and the musical professionals in the music industry, having instruments that last longer, that sound extraordinarily good, and that are strong and sturdy is very important. …

Continue reading »

|

|

Are Aluminum Die Casting Parts stronger and cheaper than Steel in 2020?

|

Are aluminum die casting parts stronger and cheaper than steel? How can an aluminum die cast part be stronger than a steel weldament? Kinetic Die Casting, Inc. makes an aluminum die casting Boomerang cam lever part for a lift manufacturer …

Continue reading »

|

Plastic Injection Companies

There are times when a plastic injection part is a better option than an aluminum die casting. When that is the case, we suggest you choose one of the following companies listed here:

Available spot for good plastic injection company (for exchange) - contact us

Available

Available

Die Casting Processes

Brass Parts Die Casting.

Tooling Die Casting.

Die Casting Draft Angle.

Alloys for Die Casting.

Aluminum Die Casting Company.

Zinc Parts Die Casting.

Magnesium Die Casting Company.

Porosity in Die Castings.

Sand Castings.

Technical Die Casting Terms.

Die Castings Compared to Steel.

Die Castings Compared to Plastic.

Capabilities of Die Casting.

Why use Diecasting.

What is Die Casting.

American Die Casting Company .

Manufacturing Die Castings .

Custom Metal Parts.

Diecast Quality Production.

Die Casting Aluminum.

Diecasting Company.

Kinetic Die Casting Company.

|